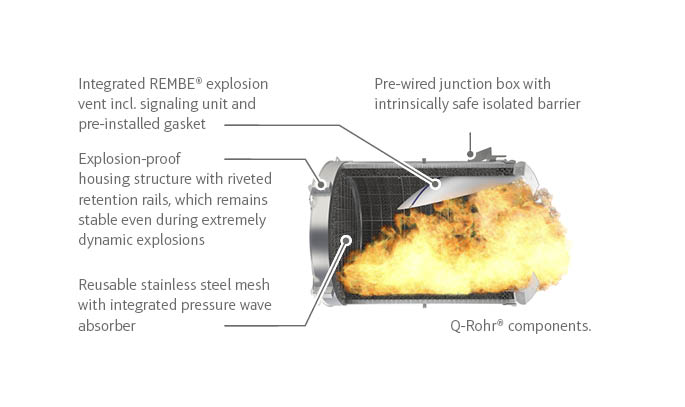

The Q-Rohr® enables you to implement flame arresting and particulate retention explosion venting in closed rooms. Safety and operating efficiency go hand in hand. No complicated ducts for outdoor venting or associated restructuring of production equipment are required.

With the Q-Rohr, there is now nothing to prevent you from using the optimum layout for your production plant while guaranteeing the best possible explosion safety. In addition, Q-Rohr® is unrivalled in terms of running costs. Eliminating vent ducts saves you money not only on installation but also on servicing and maintenance.

Q-Rohr® is also suitable for metal dusts, gas, and hygienic applications. Q-Rohr® is available in the sizes DN 200 to DN 800. Customized versions up to DN 1400 are also possible.

Application

The Q-Rohr® is ideal for indoor plants that are at risk of dust and gas explosions. Many new plants are equipped directly with the Q-Rohr® as it offers a wide range of flexible installation options.

Retrofitting is also simplicity itself. The Q-Rohr® can be used to protect filters, dryers, cyclones, and it can be used with gases, hybrid mixtures, metal dusts, melting dusts or fibers.

Optional sanitary cover prevents accumulation/ contamination of the Q-Rohr® flame trap mesh in dusty areas.

Mechanism

The special stainless steel mesh filter inlet developed by REMBE® cools the hot flame gases extremely efficiently (up to 1.500 °C (2.732 °F) for metal dusts). This reduces the volume of gas ejected and extinguishes the explosion.