Description

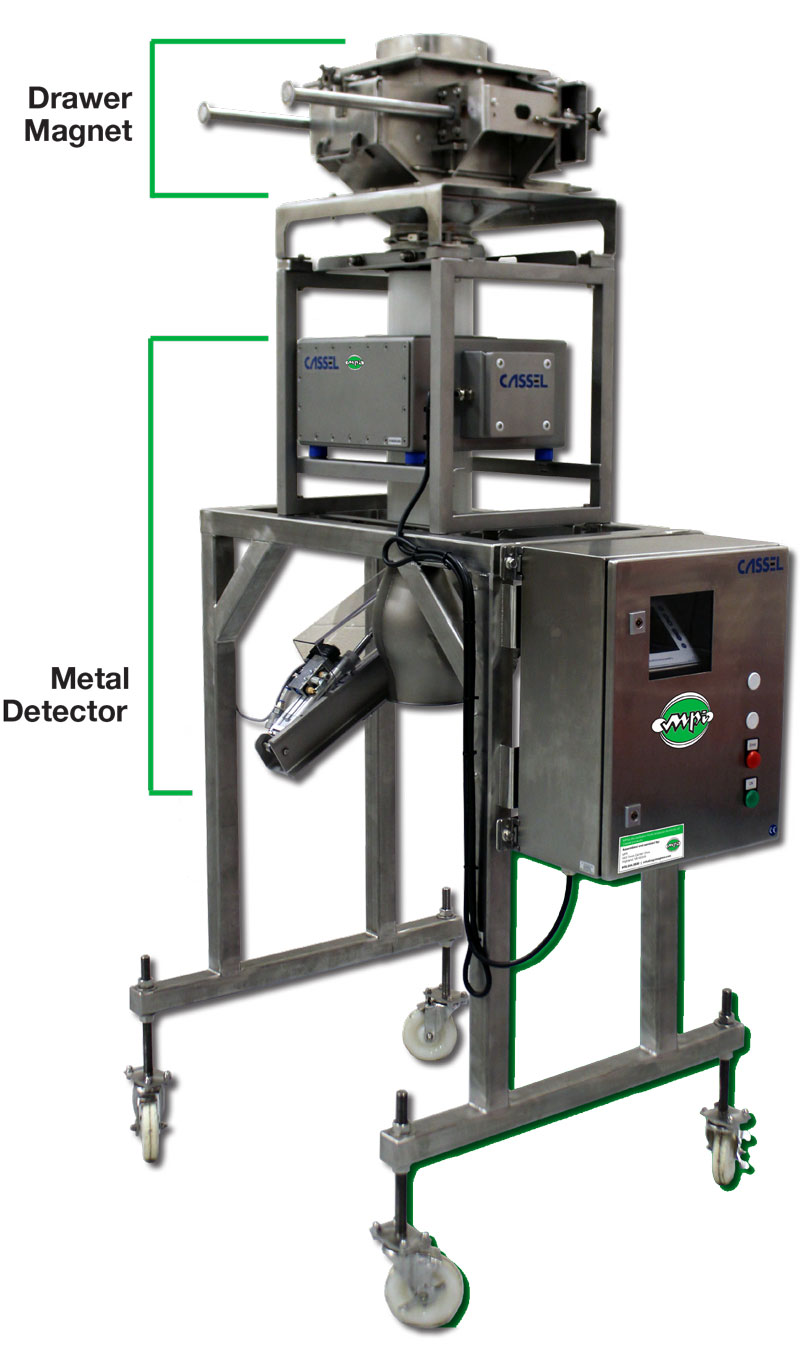

How the Pro-Tector Metal Detector Works:

Designed for use in gravity-feed pipes to monitor for metal contaminants in continuous-flowing granules or powders such as sugar, flour, corn meal, or spices, the Pro-Tector’s integrated drawer magnet provides maximum magnetic separation of contaminants. Product first flows through the drawer magnet, which is located at the top of the unit, and then ferrous-free product continues through a gravity-feed metal detector.

The Pro-Tector’s integrated drawer magnet employs twin layers of rare-earth magnetic tubes to provide maximum magnetic separation of metal contaminants, and its quick-clean feature allows the operator to clean the unit in under ten seconds.

Extremely reliable and easy to use, the Pro-Tector’s integrated metal detector features a straightforward operating system that quickly guides the user through set-up and operation.

Options:

USDA certified drawer magnet available

- SHARKNET® software

- Monitor real-time inspection results and actively manage product inspection equipment from a central computer

- Enables automatic downloading of data documentation to a Windows-based PC

- Support required compliance with: HACCP-SQF 2000-BRC-GMP-IFS5-FSSC 22000/PAS 220

- Remote maintenance capability by operators and Cassel technicians

- All data is stored in an SQL database for easy export or integration if needed

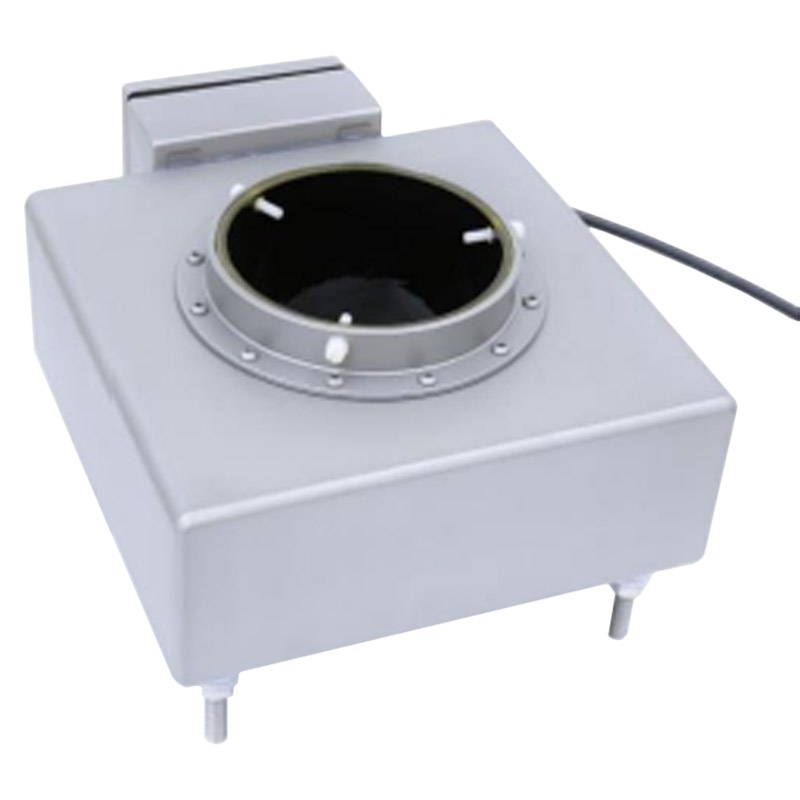

- Pro-Tector for Liquid Systems

- For more information on this system contact MPI

- Pro-Tector for Pneumatic Systems

- For more information on this system contact MPI