Description

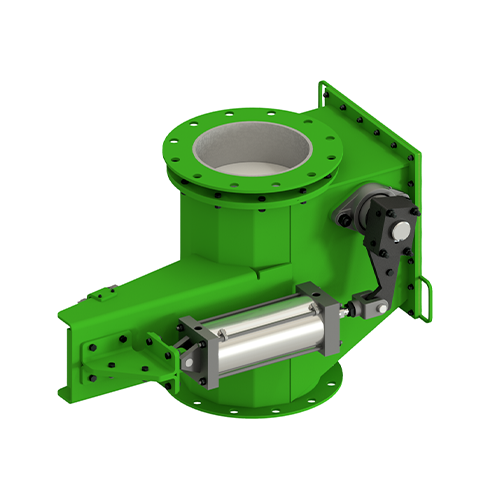

PEBCO® Positive Seal Valves feature a fully sealed and gasketed design providing self-adjusting seals for material flow. Maintenance is a cinch on these valves, as rear access allows for disc replacement without the need to remove the valve itself. More product info:

- Fully sealed and gasketed design suitable for pressures up to 14.9 psi

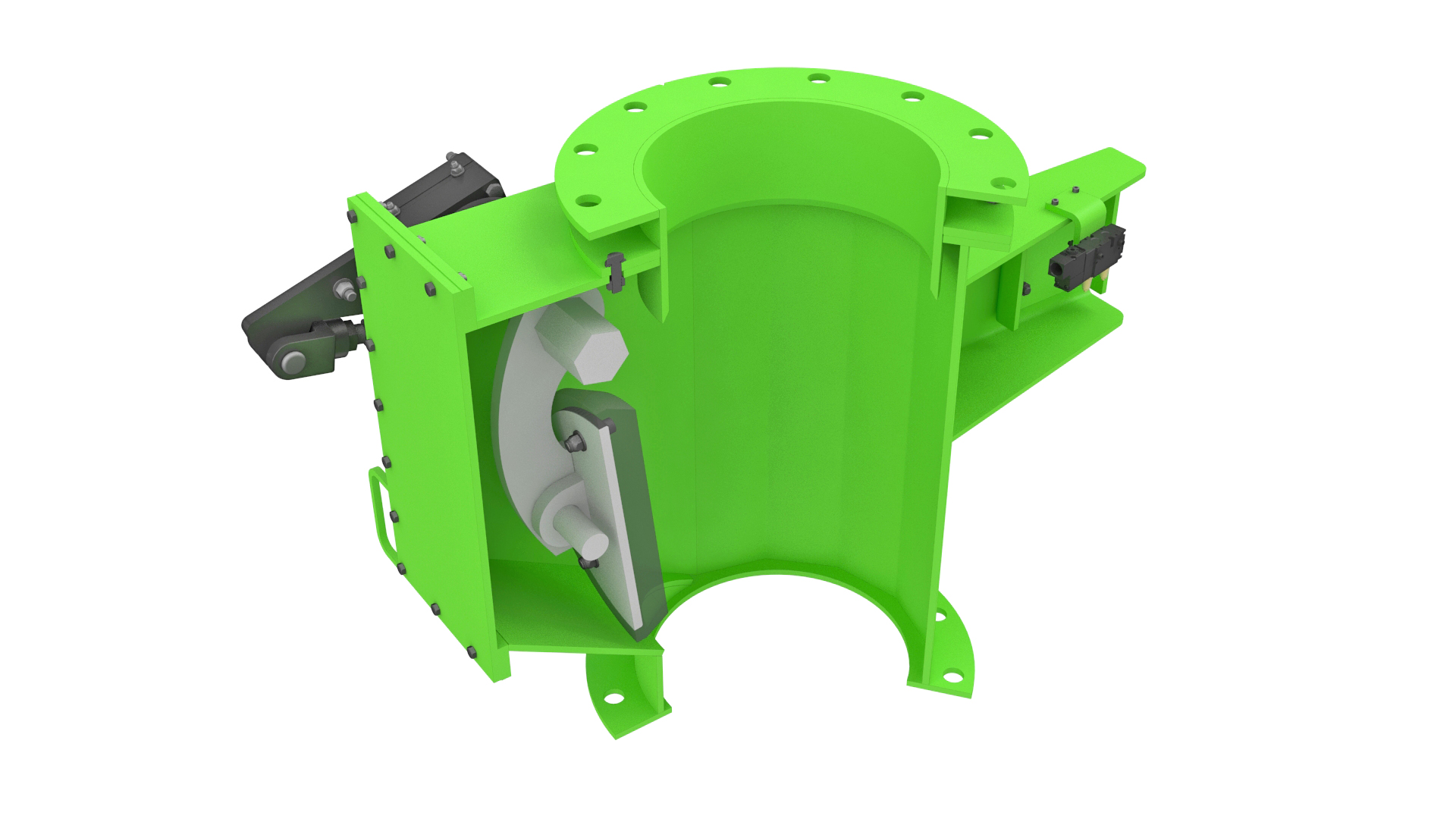

- Tapered disc and seat provide optimum, self-adjusting seal up-stream to down-stream

- Cast urethane disc compresses when closed to allow use in liquid and gas applications

- Large rear access cover allows disc replacement without removing the valve from the process line

- Pneumatic or hydraulic actuation provides constant load on sealing surfaces

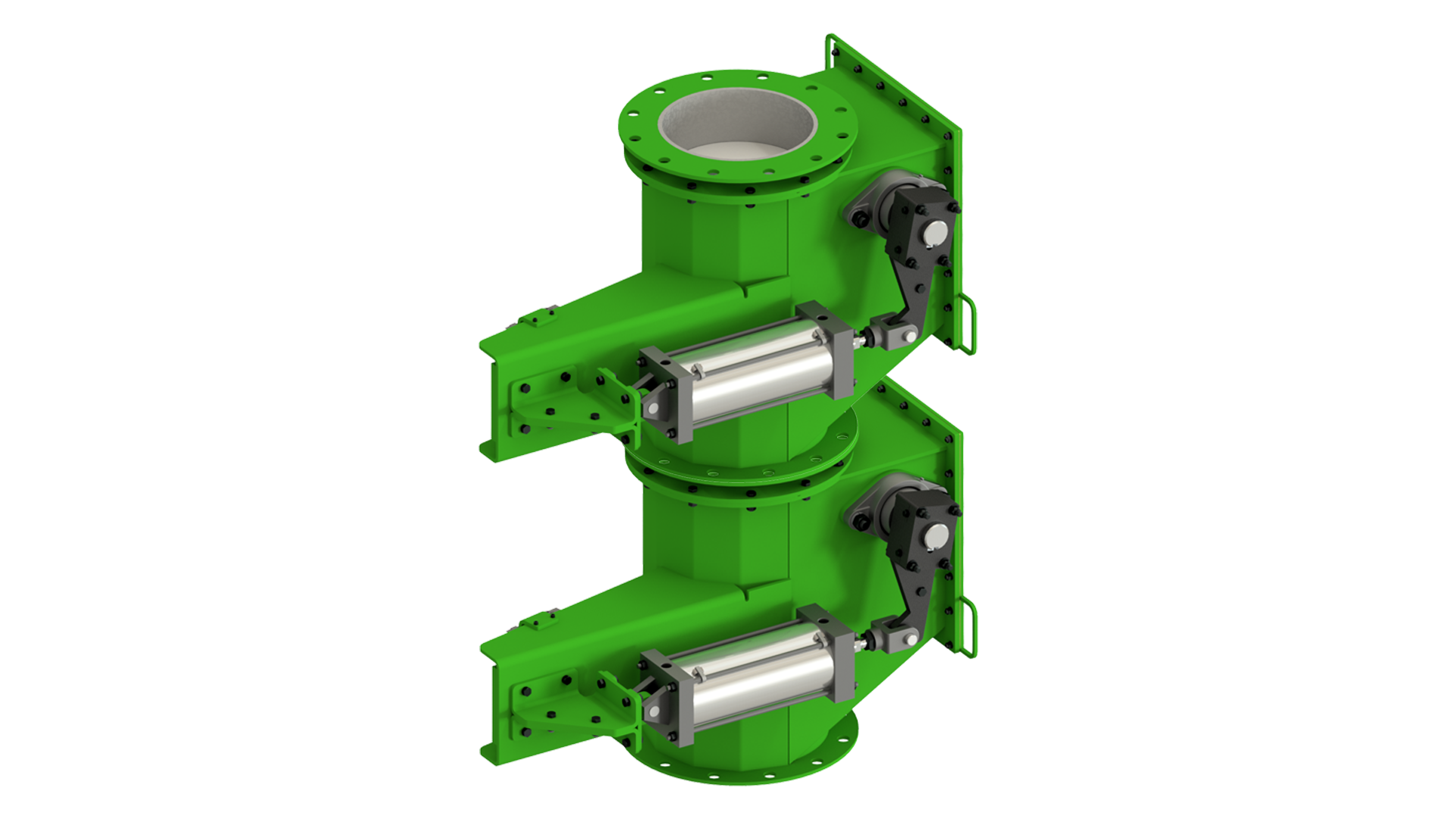

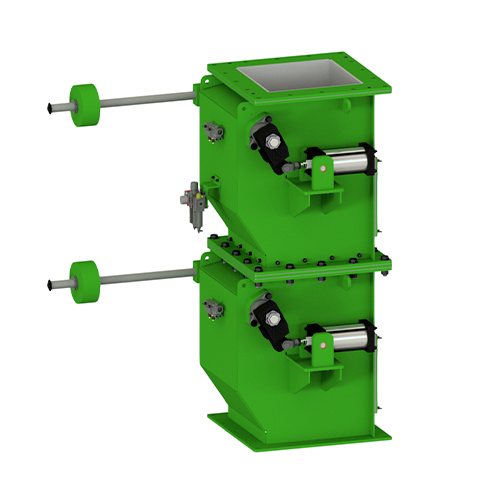

- Stack two PSVs to create an improvement on the “Double Dump Valve”

Typical applications include:

- Positive shut-off of aerated products beneath silos and fluidized conveyors

- Dust collector/cyclone discharges and pneumatic conveying

- Improved sealing and low maintenance make this an attractive replacement for rotary valves/airlocks

Optional Features:

- Polymer or metallic discs are available for special applications and/or elevated temperatures

- Outboard bearings with adjustable shaft packing for pressurized applications

- Include a spool or “dutchman” between two PSVs to increase throughput