Description

Whatever your heating or cooling needs, we can engineer and fabricate a PLATECOIL® heat exchanger to improve your process and efficiency.

- Configurable as jacketed vessels, clamp-on panels, immersion heaters, banks-in-tanks, cryogenic shrouds, mixers

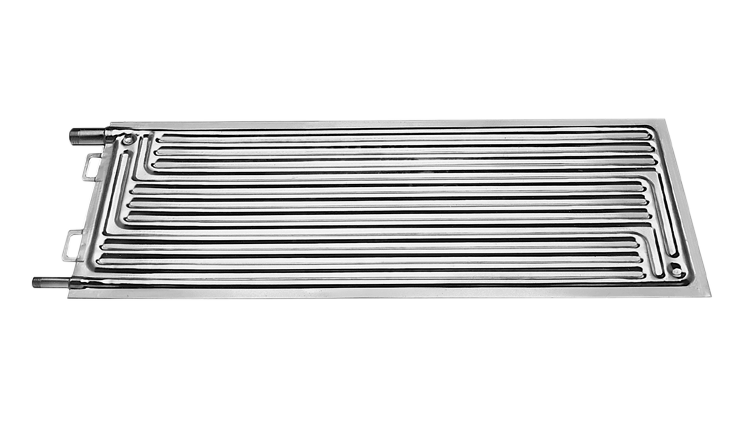

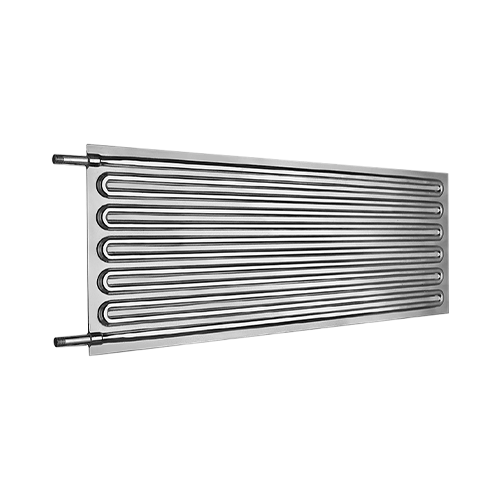

- Single-embossed or double-embossed styles may be flat, formed or rolled

- Wide range of pre-engineered and custom designs and sizes

- Unique Multi-Zone and Serpentine configurations available

- High heat transfer rates

- Quality manufactured and thoroughly tested; ASME Code available

- Fabricated in carbon steel, stainless steel and most corrosion resistant alloys

Manufacturing of PLATECOIL®

- Sheet material is pressed to form “corrugations” called embossings.

- Embossings are either seam welded to each other to form “double embossed” coils, or to a flat sheet to form “single embossed coils.

- Fittings are attached to provide an inlet & outlet for fluid internal to the PLATECOIL®.

- Carbon steel, 304 and 316 stainless steel are the standard materials of construction.

Other alloys that can be cold formed and welded are also used:

- Monel

- Inconel

- Hastealloy

- Alloy 20Cb-3

- 254-SMO

- AL6XN

- Titanium