Description

Technology

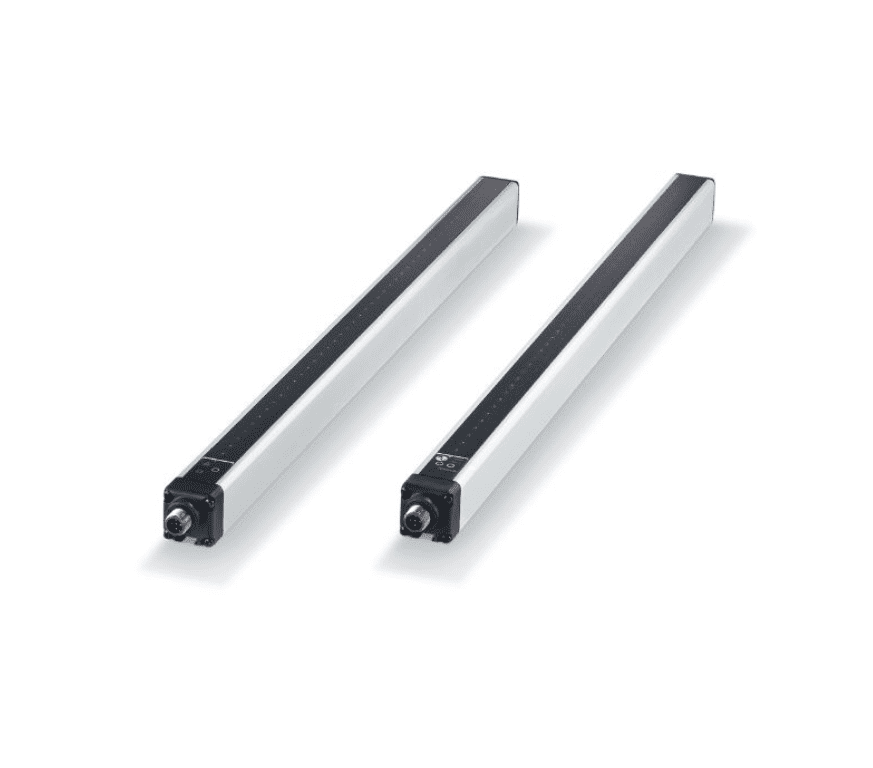

The ifm measurement light curtains operate similarly to photoelectric through-beam sensors. They consist of transmitters and receivers align in a grid format. Multiple beams of infrared light are transmitted across a space to a mechanically aligned receivers.

Measured area height and width

The measured area height (H) is not the overall height of the light curtain. Rather, it is the area between the first and last light beams. ifm’s measurement light curtains cover heights from 140…2540 mm in increments of 150 mm.

The measured area width (W) is the distance between the transmitter and receiver. ifm’s measurement light curtains can be mounted from 1…10 m apart.

Resolution

Resolution is the sum of the diameter of a beam and the center-to-center distance between adjacent beams. Objects larger than the resolution break the beam. The smaller the resolution, the smaller the object the light curtain can detect. ifm’s measurement light curtains all have 10 mm resolution.