Magnetic Stacking and De-Stacking Conveyors

Bunting® Stacking Modules can be configured to take sheets or blanks from your cut-to-length operation and then transfer, index, and stack them at pre-selected destination points. Stampings can be conveyed away from your press die area into a stack.

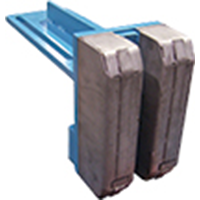

A magnetic sheet fanner unit can be installed to fan and separate stacked parts or blanks and feed them one at a time into production machinery. As the ferrous sheets or parts are acquired and magnetically fanned, they are separated and lifted one at a time by the suction cups to the overhead magnetic conveyor and transported to the next workstation.

Application Datasheet – Fill Out and Return for Most Accurate Quote