Description

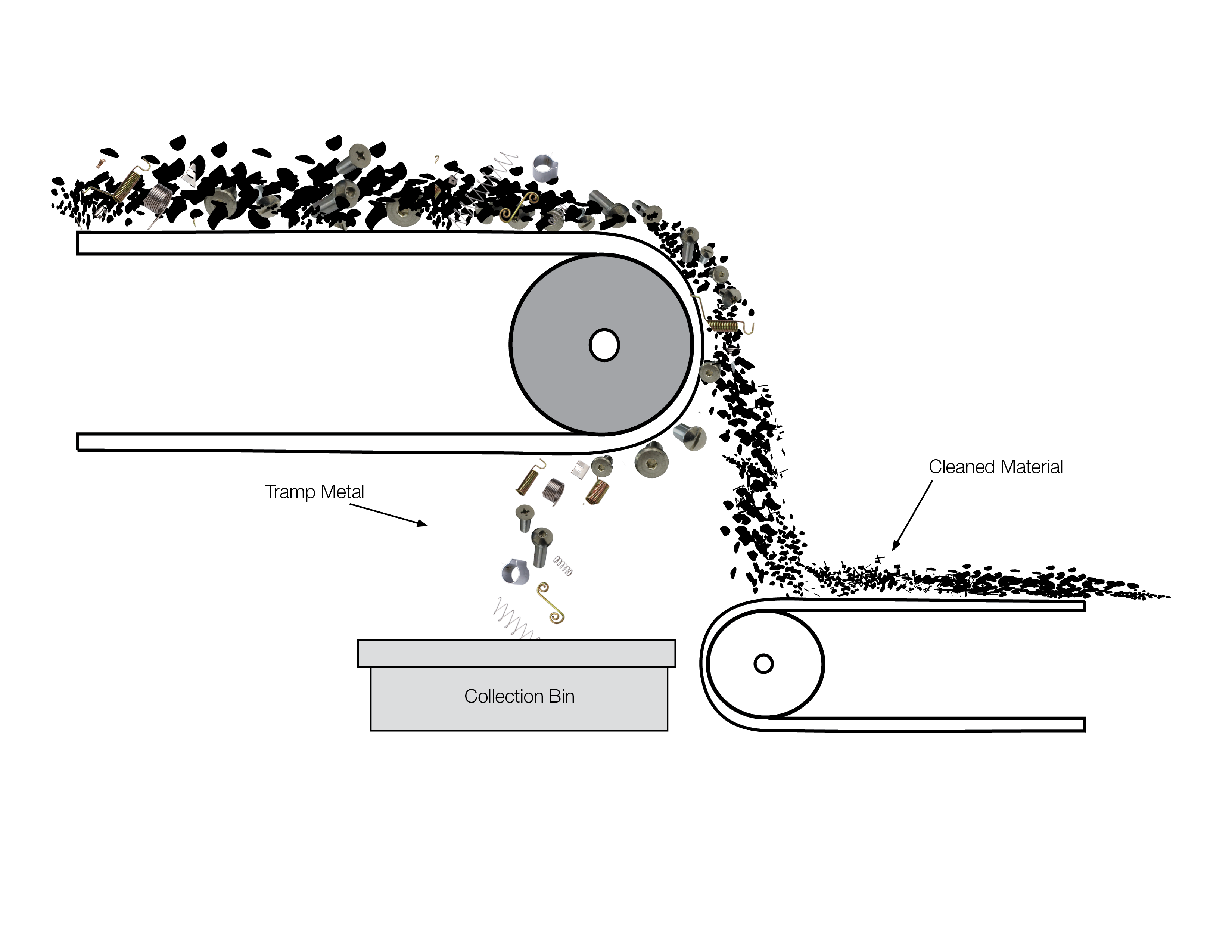

How the Magnetic Belt Feeder Works:

As the product reaches the end of the feeder’s conveyor, it passes through a magnetic field. Gravity causes clean, non-ferrous materials to exit and fall away from the MBF system. Ferrous metals are carried around the head pulley and are transported away from the magnetic field where they fall from the conveyor belt typically into a metal collections area.

Options:

- Custom motor voltages, belt speed, delivery/discharge transitions

- Ceramic or rare earth magnet material

- Welded or bolt-on legs

- Magnetic roll circuitry: Axial, Radial