Description

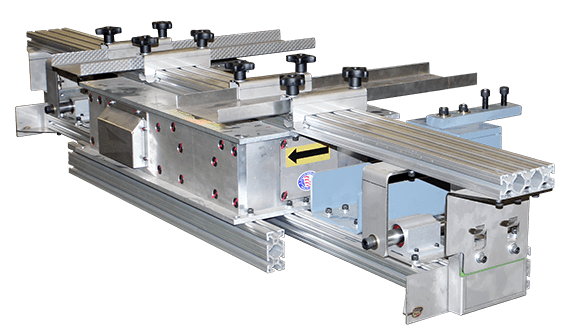

How the M-200 Electric Scrap Shaker Works:

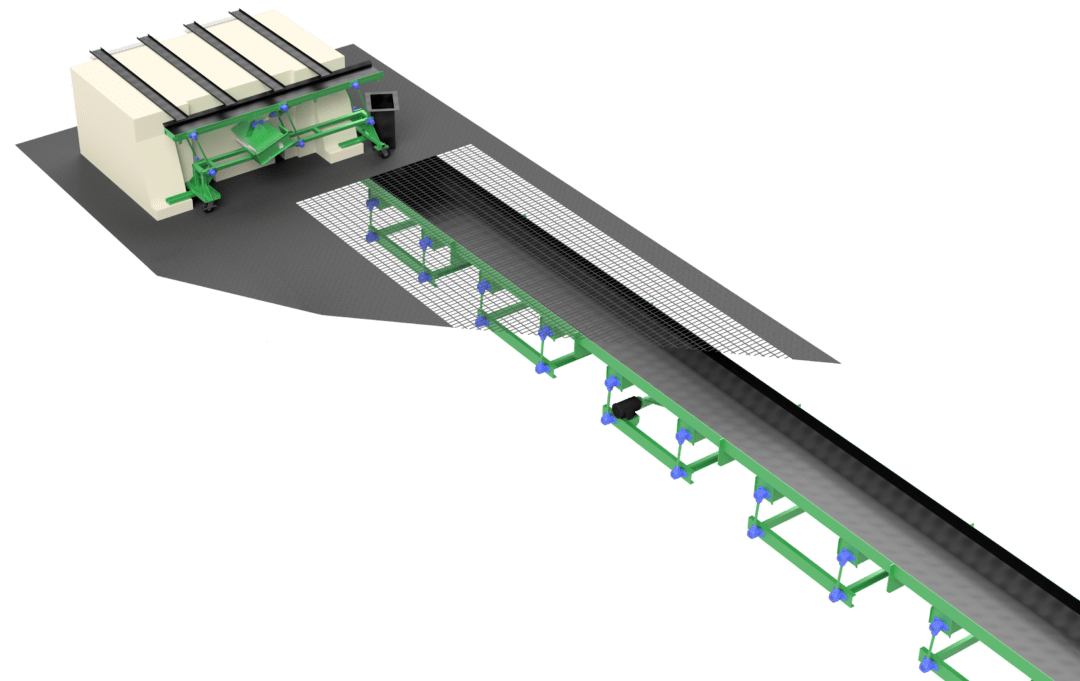

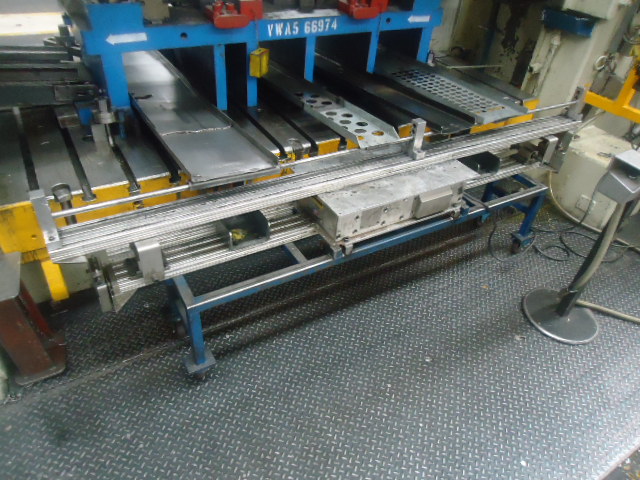

Metal coils feed stamping presses at throughputs of up to 100 parts per minute. After each punch, metal trim falls away through the die, onto a shaker pan mounted underneath. The electric scrap shaker conveyor motor then “shakes” the pan and conveys the trim scrap into a collection bin for recycling or sale.

M-200 Electric Scrap Shaker Options:

- T-slot motor mounts

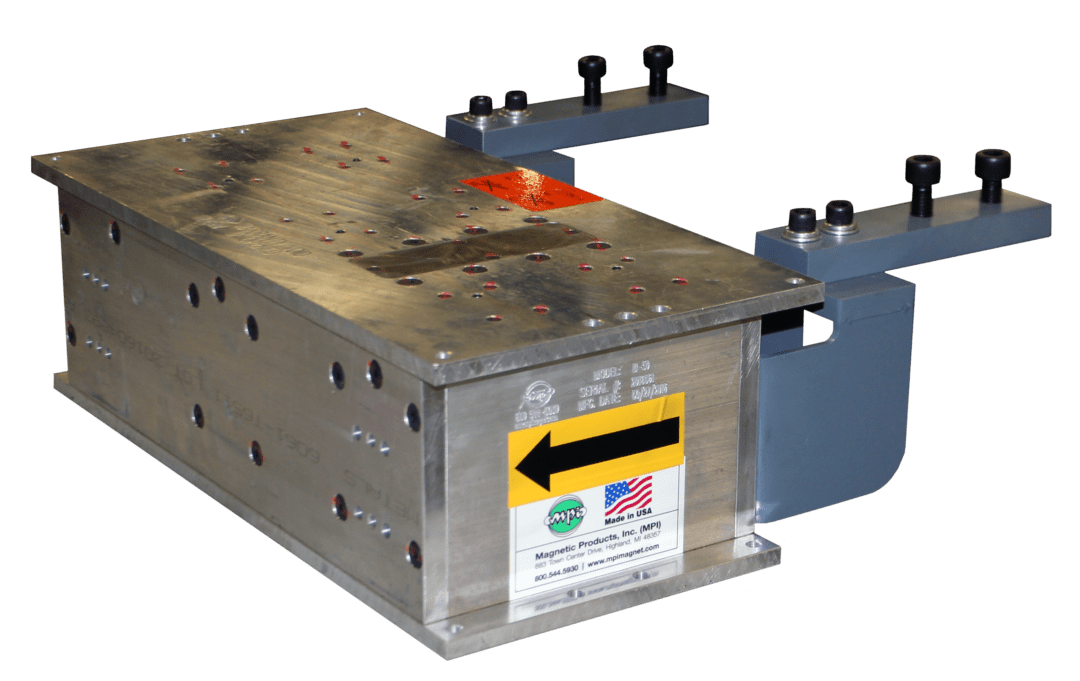

- Rack and pinion system

- MPI Rack and pinion systems are designed to allow our electric shakers the ability to handle uneven or offset pan loads without damage. The rack and pinion design provides support so offset weight is evenly distributed no matter the mounting location on the cross bar.

- When a shaker is subjected to uneven pan loads the bearings begin to pull out of alignment. As the shaker continues to move back and forth, the bearings continue to give way and the shaker becomes internally unbalanced. The internal components begin to interfere with each other, eventually resulting in motor failure.

- Custom shaker trays

- Aluminum extrusions cut to length

- Height adjustable cart

- Wear pad kits

- Quick release pan mounting brackets

Application Data Sheet – Fill Out and Return for Accurate Quote