Description

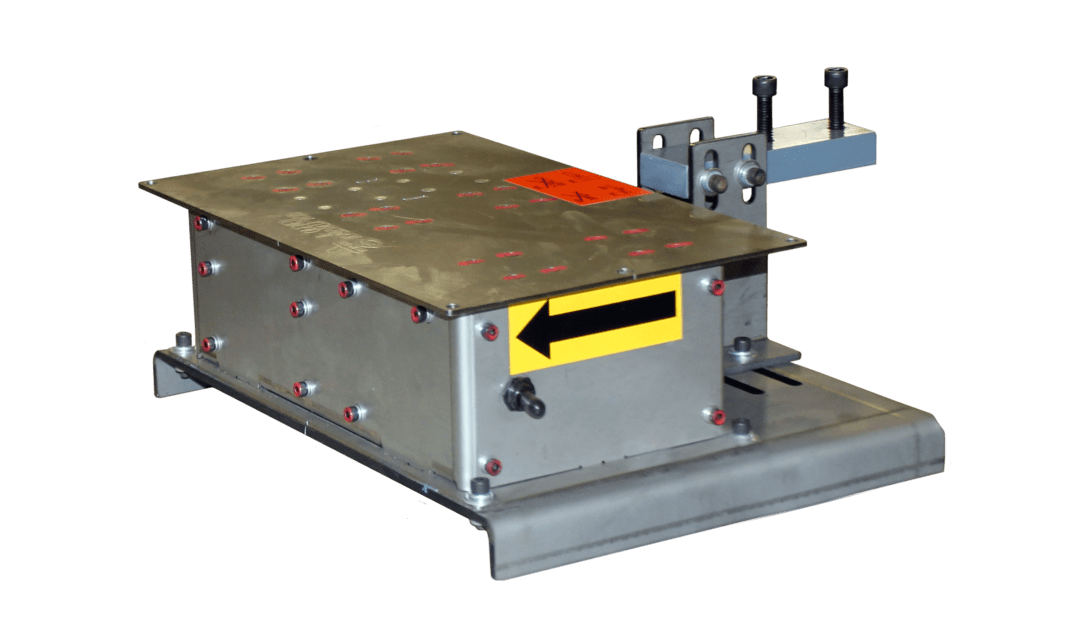

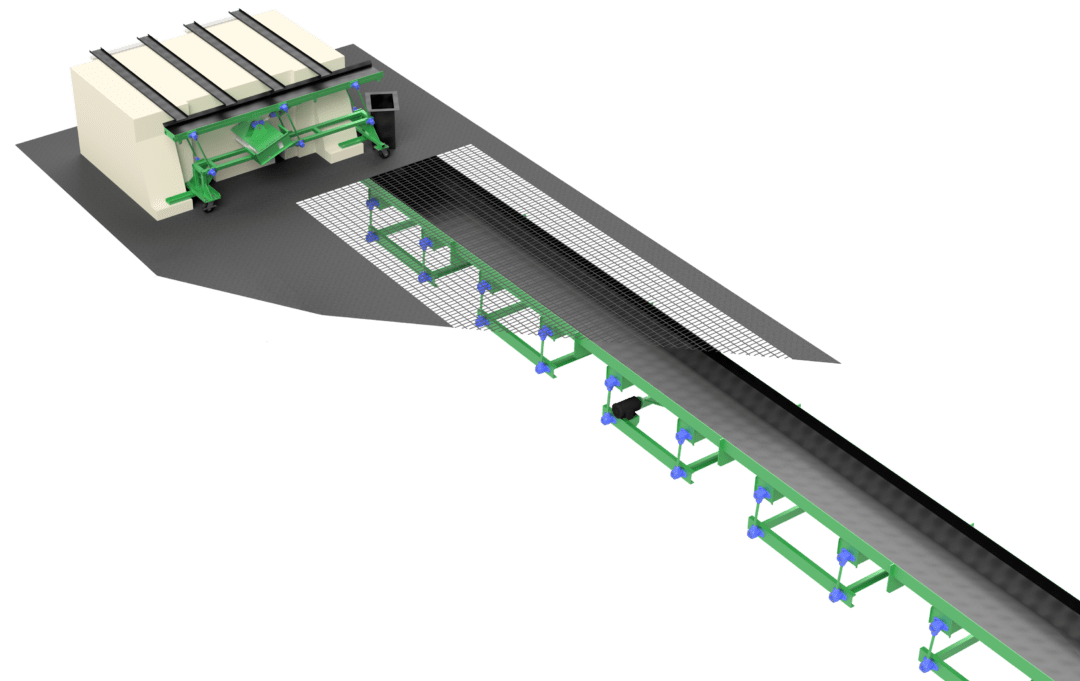

How the M-10 Electric Scrap Shaker Works:

Metal coils feed stamping presses at throughputs of up to 100 parts per minute. After each punch, metal trim falls away through the die, onto a shaker pan mounted underneath. The electric scrap shaker conveyor motor then “shakes” the pan and conveys the trim scrap into a collection bin for recycling or sale.

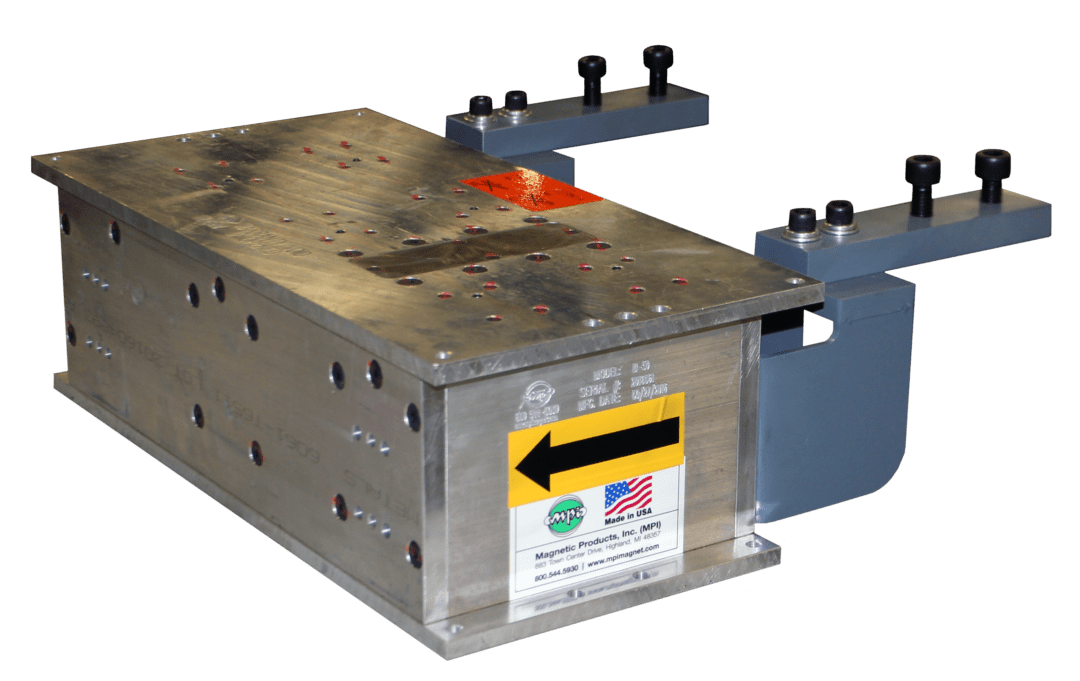

M-10 Electric Scrap Shaker Options:

- Custom shaker trays

- Quick Release Pan Mounting Brackets

- Wear pad kits

Application Data Sheet – Fill Out and Return for Accurate Quote