Description

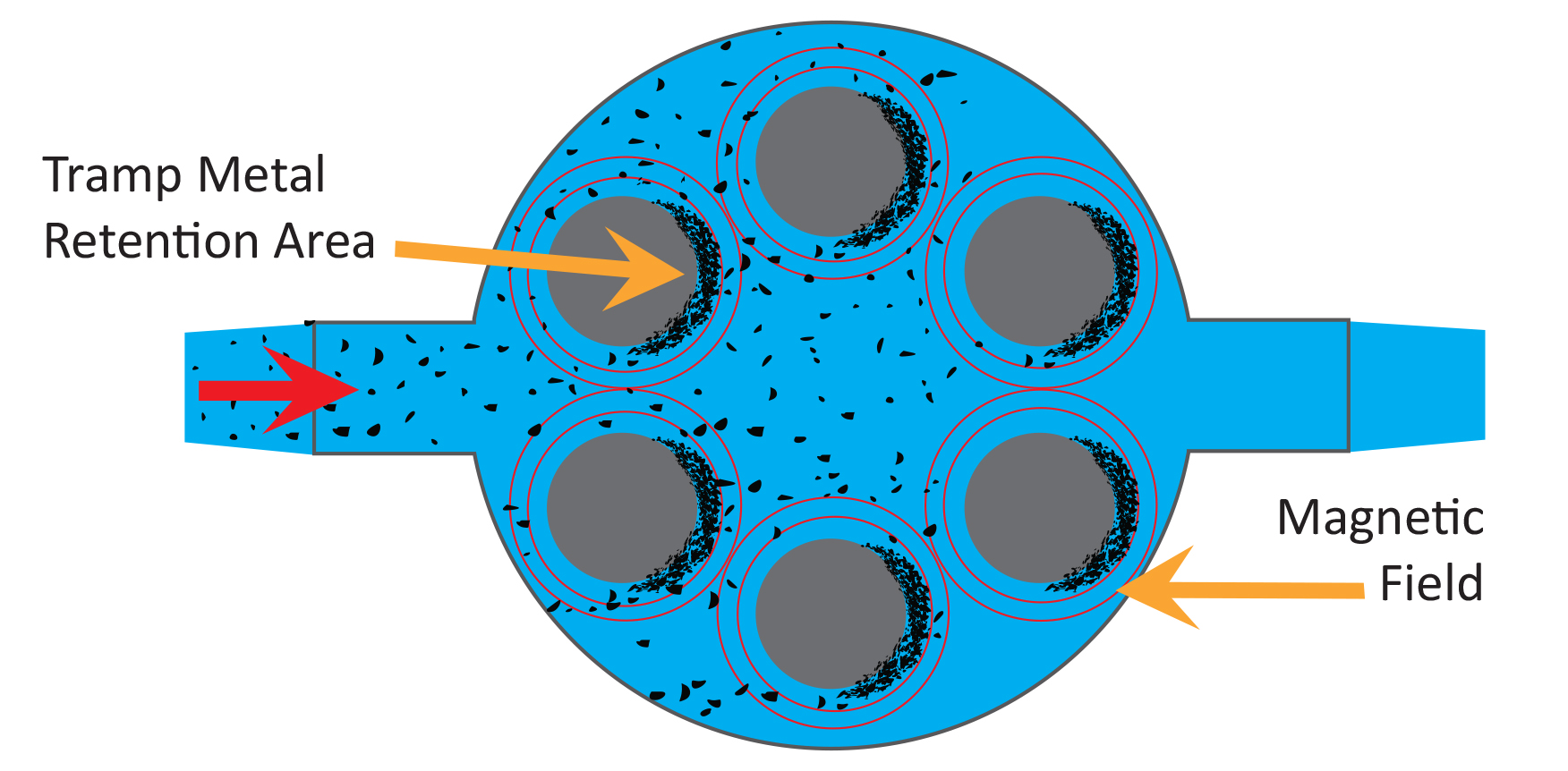

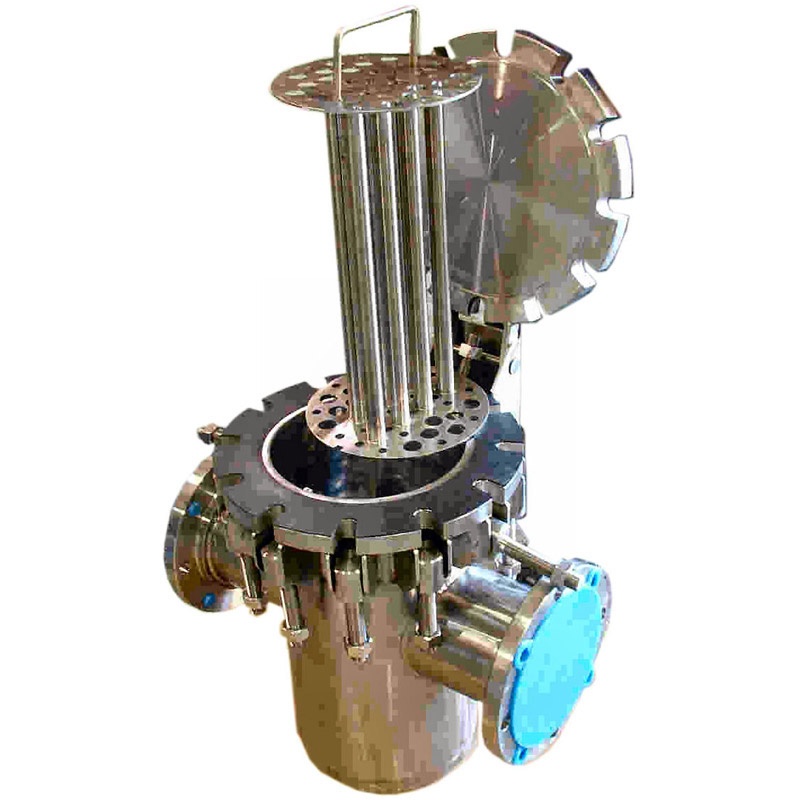

How Liquid Fingertrap Tube Magnets Work:

The tramp metal collects at the downstream side of the magnetic tubes, preventing tramp metal “wash-off” during the continuous product flow around and through the magnetic field without restricting the product flow. Additionally, non-magnetic particles are trapped, by gravity, in a sump beneath the magnetic element.

Liquid Fingertrap Tube Magnet Options:

- Pipe Size: Available in diameters from 1” to 6” in any increment.

- Maximum Operating Pressure:

- 150 PSI at 248°F (120°C) (standard on sizes 4” and smaller)

- 75 PSI at 248°F (120°C) (standard on sizes 5” and larger)

- Cleaning Method:

- Manual clean (standard)

- Manual quick-clean with a sleeve over stripper for easy removal of tramp metal. Not recommended for sticky products. Sleeve over design reduces magnetic performance at contact.

- Magnet Element: Four different styles are available depending on your application

- Array of 1” diameter tubes designed for liquids, purees, and products with solids 1/2” and smaller

- Single 3” diameter tube mounted in the center of housing designed for products with fragments, solids or chucks up to 1” in size

- Plate magnet design with one or two plate magnets mounted on the outside of the product flow for very difficult flowing and fibrous products

- Combination magnet and screen design

- Material Construction:

- 304 Stainless Steel (standard)

- 316 Stainless Steel

- Magnetic Tubes:

- REN Rare Earth (standard)

- Hi-G high-performance Rare Earth

- TW Thin Wall high-performance Rare Earth

- Magnetic Material Temperature:

- 176°F (80°C) @ 52+ MGOe (rare earth) (standard)

- 248°F (120°C) @ 48 MGO (rare earth)

- 356°F (180°C) @ 38 MGO (rare earth)

- 662°F (350°C) @ 30 MGO (rare earth)

- Tube Coatings:

- Stainless steel with no coating (standard)

- Synergistic Coating [reference datasheet Synergistic Coating]

- Gasket Material:

- Buna material, color red, metal detectable, temperature range: -40°F (-40°C) to 225°F (107°C) (standard)

- Viton material, color white, temperature range: -10°F (-23°C) to 400°F (204°C)

- Customer specified

- Inlet Flange Design:

- Tri-Clover sanitary heavy-duty quick-release clamp (standard)

- NPT threads (for use of spin on flanges)

- ANSI 150 pound flange

- Plain end for welded pipe installation

- Customer specified

- Outlet Flange Design:

- Tri-Clover sanitary heavy-duty quick-release clamp (standard)

- NPT threads (for use of spin on flanges)

- ANSI 150 pound flange

- Plain end for welded pipe installation

- Customer specified

- Water Jacket: For heating or cooling products

- Not included (standard)

- Included

- Drain: Ball valve located on the bottom of the unit to drain before opening the magnet

- Not included (standard)

- Included

- Lock Out Tab: Prevents unauthorized entry via customer supplied and an installed padlock

- Not included (standard)

- Included

- USDA Magnet Certification:

- Not included (standard)