Description

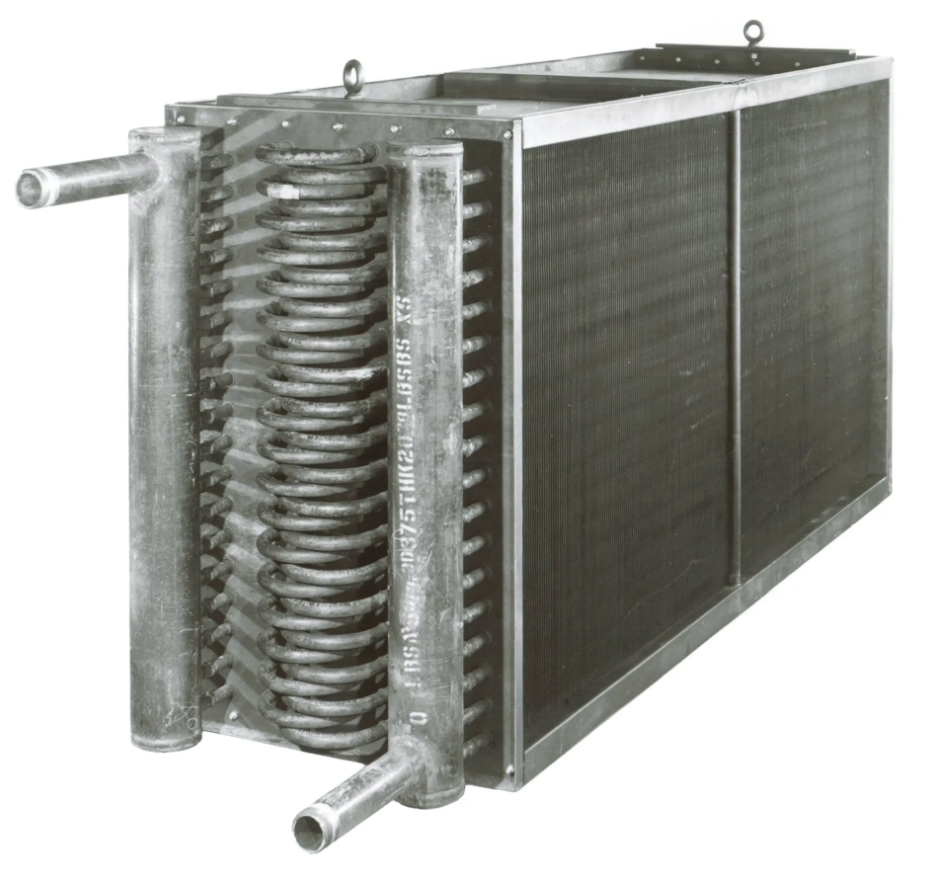

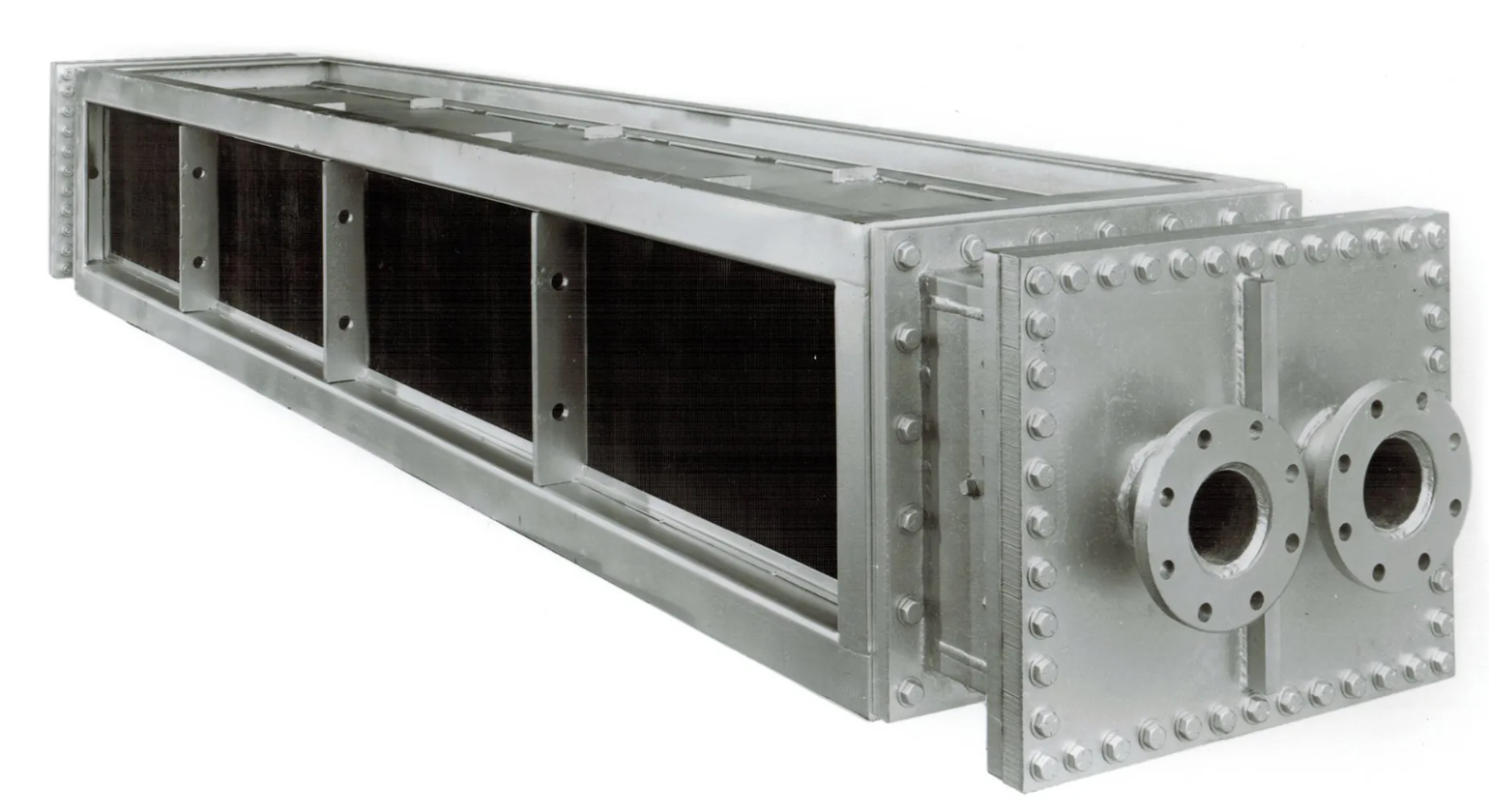

Internal liquid side pressures on hot oil coils range from 50 to 300 PSIG with temperatures of 0 degrees to 800 degrees fahrenheit. Airside temperatures range from -10 degrees to 1200 degrees fahrenheit. These wide variables in pressures and temperatures put many stresses and strains on the coils in the system. The coils are subjected to expansion, contraction, and thermal shock that could be as high as 4,000 or 5,000 PSIG, especially during start-up or venting operations, thus the need for strong coils with welded joints.

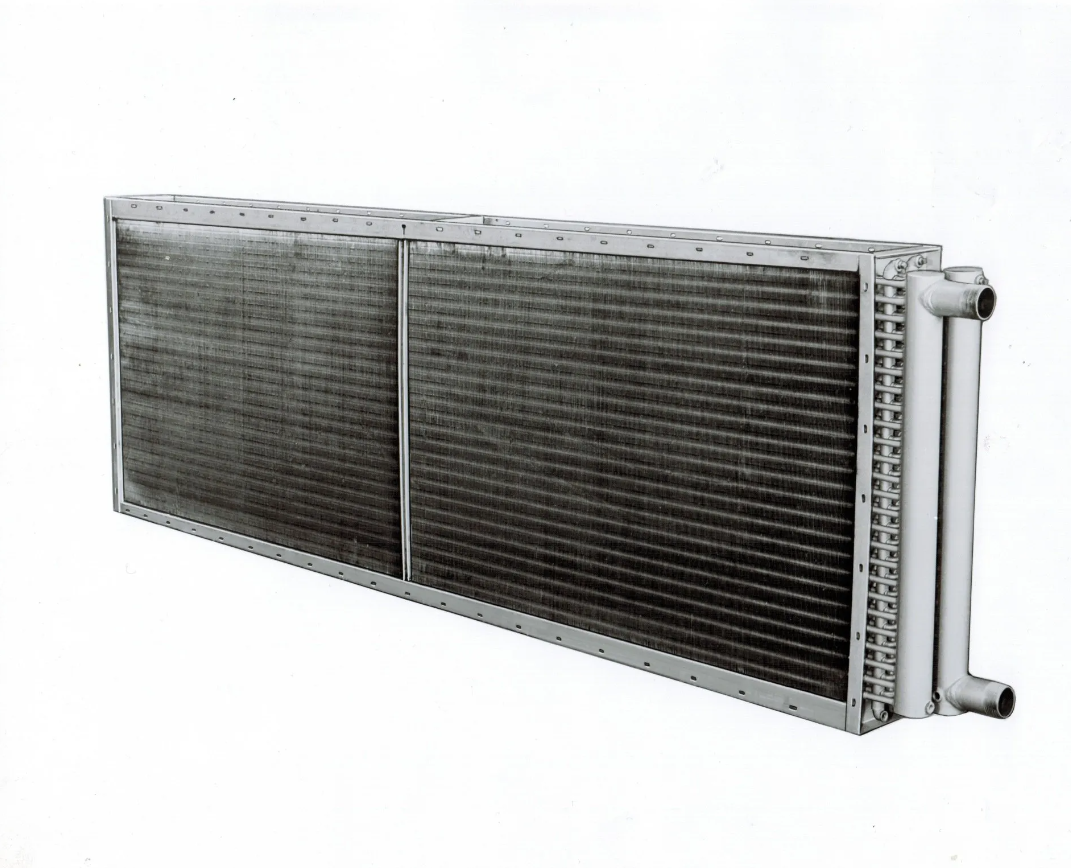

Heavy continuous flat plate type fin with wide fin spacing makes plugging less likely to occur. Heavier fin can withstand the extreme demands and abusive conditions prevalent in industrial applications and is more likely to handle the abuse of a high pressure hot water or steam wash down during a routine cleaning, without the fins collapsing