Description

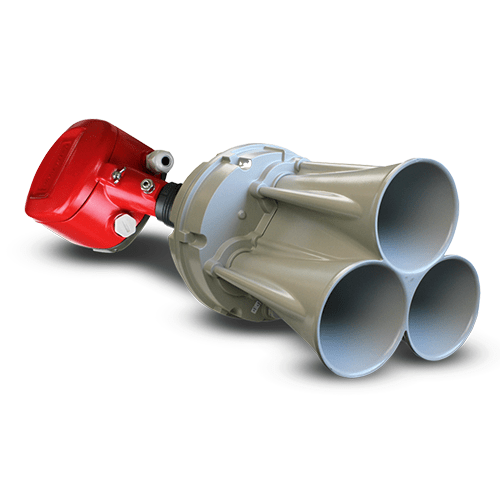

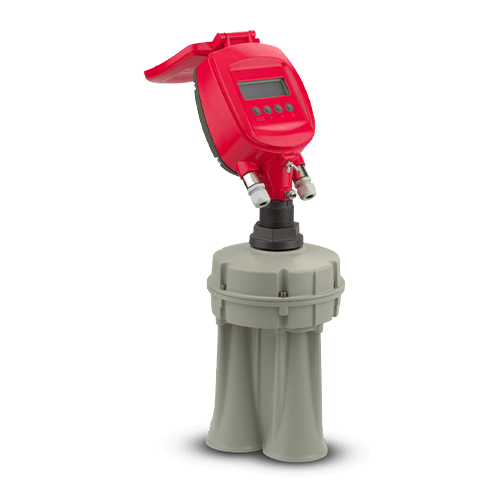

3DLevelScanner HT: Accurate Volume in High Temps

Use the 3D HT in an operating temperature range up to 356°F (180°C) to accommodate higher temperatures in materials that are heated in the production process and then conveyed into storage.

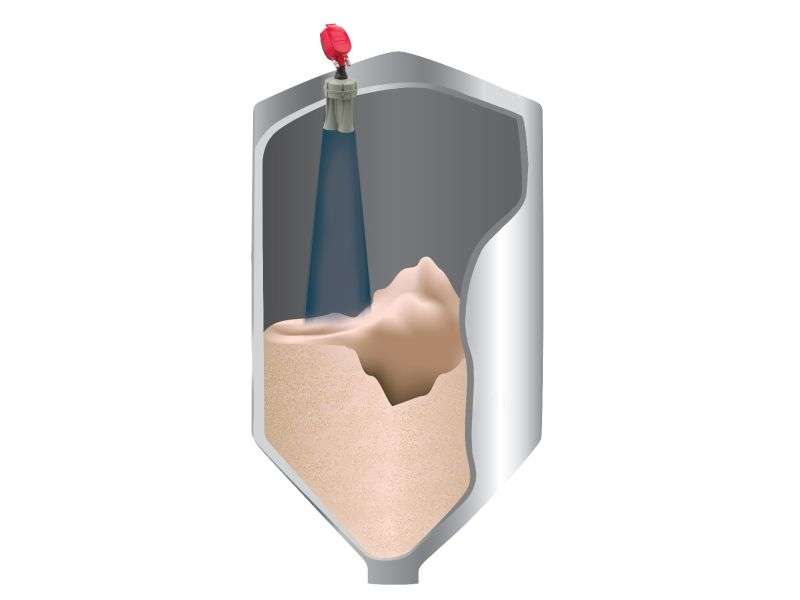

Do you process at high temps before storage? Need a sensor that can detect irregular piling?

Advanced acoustics-based technology that works in dusty silos and high temps.

Common uses for the 3D HT:

- Measuring the level and estimating the volume in storage silos containing high-temperature materials

- Silos with materials generating high dust and humidity

- Large silos with uneven and difficult-to-measure material surfaces

- Challenging materials such as clinker, alumina, frac sand, and fly ash

- Industries including cement, powder, aluminum, and frac sand

5 Ways 3D HT is different:

- Measures multiple points, not just a single distance

- Optional 3D visualization of material topography

- Detects cone up, cone down, and sidewall buildup

- Provides minimum, maximum, and average distances

- Accounts for surface irregularities for accurate bin volume