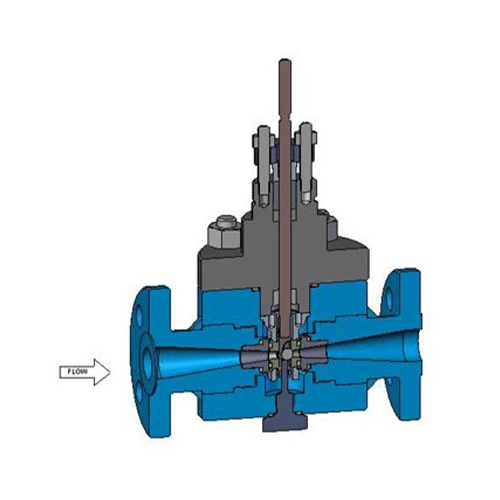

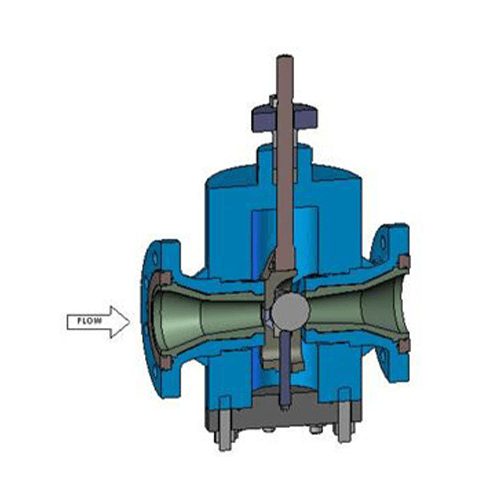

HI-100® Severe Service Control Valve

The HI-100® Control Valve features an in-line Straight-thru, venturi flow design. The control element, a spherical ball, is contained by a cage that positions the ball relative to the downstream seat by means of linear stem travel. There are no close clearances between the moving parts (i.e. cage, ball and seat). These features enable the valve to operate smoothly and efficiently at high or low temperatures, and/or in fluids carrying suspended particles such as slurries.

The Quick Change Trim feature permits in-line replacement of the internal trim (ball, stem, cage, seats, seat retainer cartridge and wear bushings). Interchangeability of the upstream and downstream seats and wear bushings extends the life of the valve and allows for a reduced operating cost when compared to the competition.

- Straight-thru design

- 1/4″ to 8″ (End Connection to 12″)

- ANSI 150 to 4500 and Special High Pressure

- Carbon Steel, Alloy Steel, Stainless and High Alloys

- Weld End, Flanged or Custom End Prep

- Temperatures: -425ºF to 1900ºF

- In-Line repair

- Quick Change Trim

- Top or Bottom Entry

- Low Operating Thrust

- Manual, Pneumatic, Electric and Hydraulic Actuation

Application Datasheet – Fill Out and Return for Accurate Quote