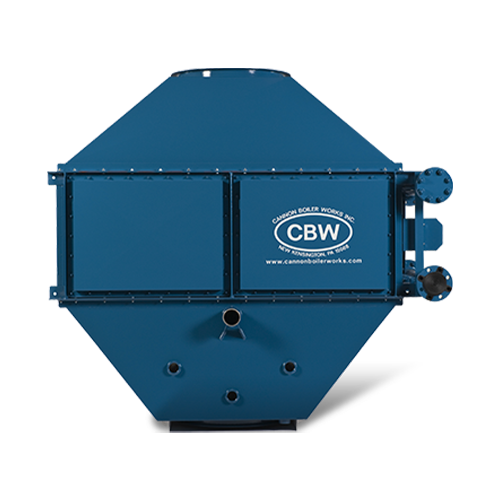

Gas Condensing Water Heaters

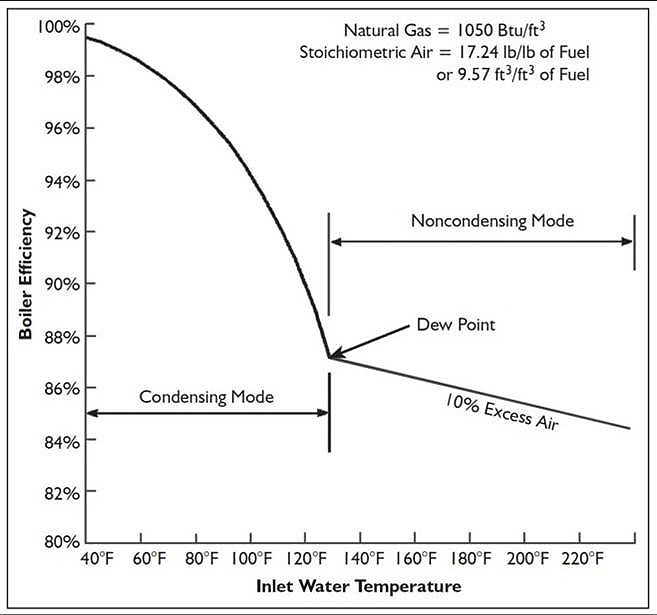

What is the difference between a regular economizer and a condensing economizer? The difference is the temperature range in which the economizer is operated. Our water heater units may look identical in outward appearance, but can be used in a condensing application if originally design to do so. A traditional economizer is operated in a hot environment, the tubes and the flue gases are over 200°F. A condensing economizer water heater operates in a cool environment, where the tubes and flue gasses may be well under 150°F. A large savings increase occurs when the flue gas temperature is decreased to under 135°F, but this is only effective when burning natural gas. Potential corrosion of the stack downstream can be addressed by upgrading the materials of the stack.

To get the best heat recovery, entering water temperatures should be in the range of 40F to 100F. This captures the most latent heat from the flue, and therefore the provides best Return on Investment

All CBW condensing water heaters feature stainless steel construction, the norm for this application, and we have several grades of stainless to choose from for many of the components in the unit.

Flue baffles and water drains are included to remove water condensed from the flue gas. This water is normally sent floor drains, but can be treated and reused (with extra equipment).

Application Datasheet – Fill Out and Return for Accurate Quote