Description

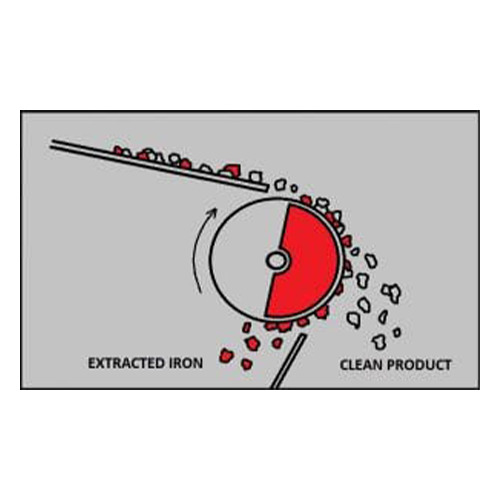

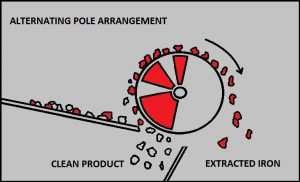

The FED, or Frag Electro Drum, is designed to provide maximum purity of recovered ferrous metals. It continuously removes ferrous metals from a product stream using an alternate pole design. This method maximizes ferrous purity. It is typically used in applications such municipal recycling and automobile recycling facilities where the ferrous fraction is recovered from the shredded material stream.

Key design features include:

- Axial pole design provides continuous high field strength at the separation zone. Effective magnet width is maximized as a result, ensuring even cover wear and minimum burden depth of material

- High-intensity primary coil concentrates maximum flux at extraction point, while the lower-intensity secondary coil facilitates transport of ferrous material to discharge point.

- Ducted coils provide improved coiling, resulting in a low winding temperature that permits higher intensity and a longer coil life.

- Wear covers are 8mm thick (minimum) in manganese steel, and incorporates bolted joints to allow easy cover replacement.

The magnetic field here alternates—this “flips” the magnetic material while it is traveling around the drum. By doing this, stray non-magnetic particles fall or are removed from the product stream. This produces a cleaner magnet product.

The magnetic field here alternates—this “flips” the magnetic material while it is traveling around the drum. By doing this, stray non-magnetic particles fall or are removed from the product stream. This produces a cleaner magnet product.