Description

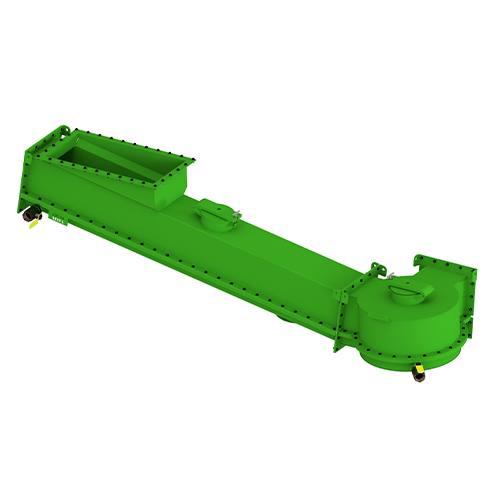

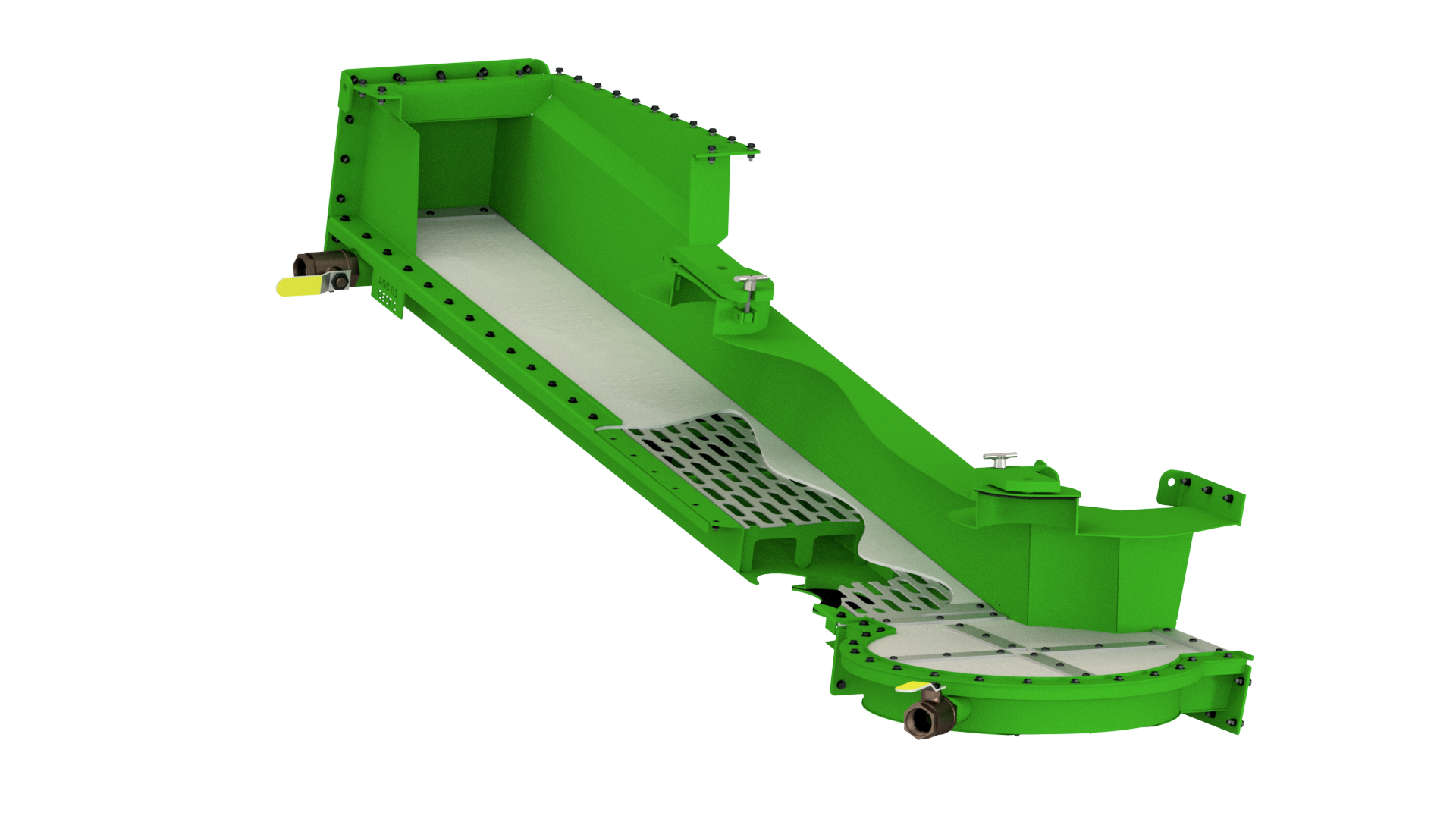

PEBCO® Fluidized Conveyors are capable of accommodating a wide variety of flow rates and feature inspection/cleanout covers on both the top and bottom of the conveyor.

- Available in a wide variety of sizes to accommodate different flow rates

- Typical lengths are 10’ and less. Assemble multiple sections for longer runs

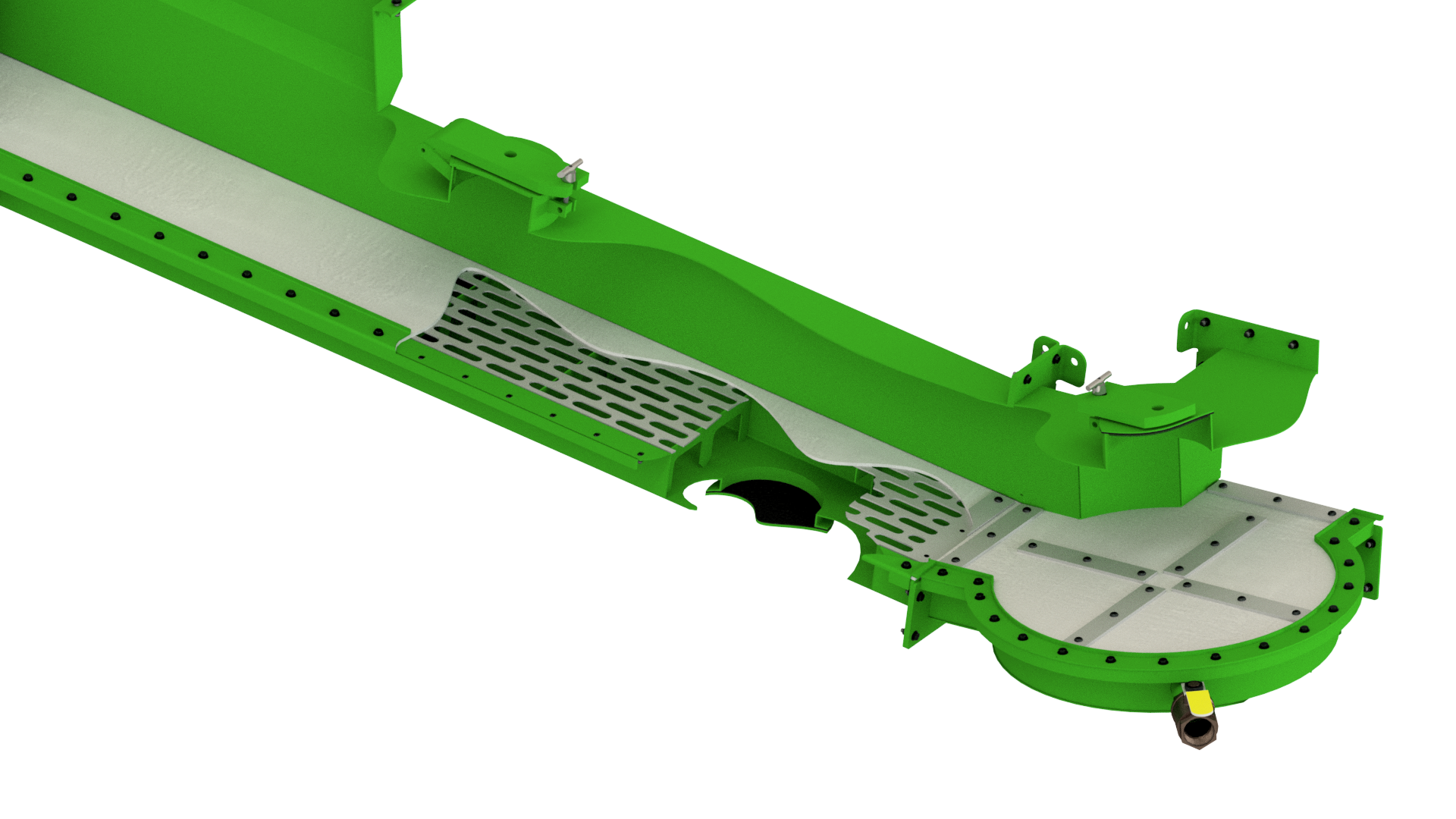

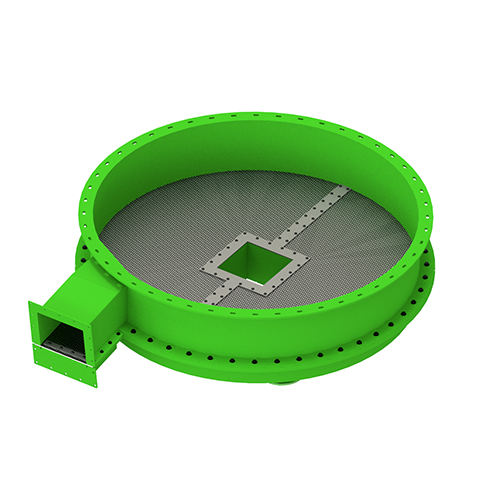

- Media supported on laser cut support grating:

- Grating is less abrasive to underside of media resulting in longer life

- Grating is mechanically trapped in the assembly, not welded, allowing for easier cleanout

- 2” NPT inlets with ball valves to regulate airflow

- Top and bottom inspection and cleanout covers

- Lifting lugs integrated into flanges

- Each section includes and integral laser cut identification plate