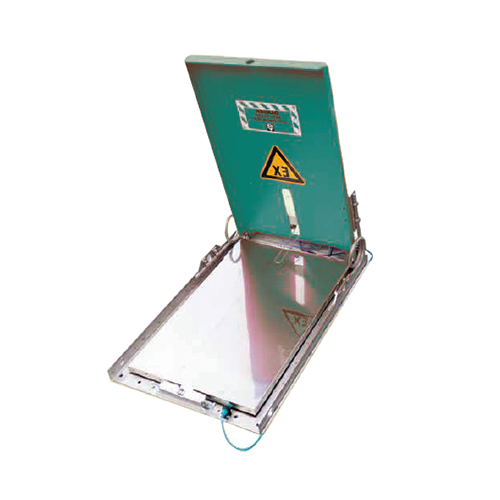

Explosion Door ETX™

EXPLOSION DOOR ETX™

Self-Reclosing and Reusable

Applications:

Drying processes in the food industry are often associated with the generation of explosive atmospheres.

The applicaton of explosion protective systems is imperative, in particular due to the high probability-occurrence of glowing embers and hot surfaces.

As a result of the function-related elongated design of ring dryers, post-explosion-fires in ring dryers are boosted by the so-called chimney effect, if the pressure relief devices remain open after an explosion.

The REMBE® explosion door ETX™ prevents post-explosion-fires by self-reclosing after the explosion pressure has been relieved, thus preventing the supply of oxygen to the air.

After successful relief the ETX™ will remain undamaged and will be ready for the next usage.

Mechanism:

The explosion door ETX™ is based on the air cushion principle. In the event of an explosion, the hinged lid will open extremely quickly, and will then be stopped by the integrated baffle plate. The integrated air cushion dampens the transmission of the kinetic energy to the rigid parts of the ETX™, and ensures that the lid of the ETX™ returns to its original, closed normal position after the explosion pressure has been relieved.

Your advantages:

- Prevents chimney-effect related post-explosion-fires.

- Self-reclosing.

- Reusable.

- High venting efficiency.

- Trace heating to maintain a snow and ice freeness (optional)