Description

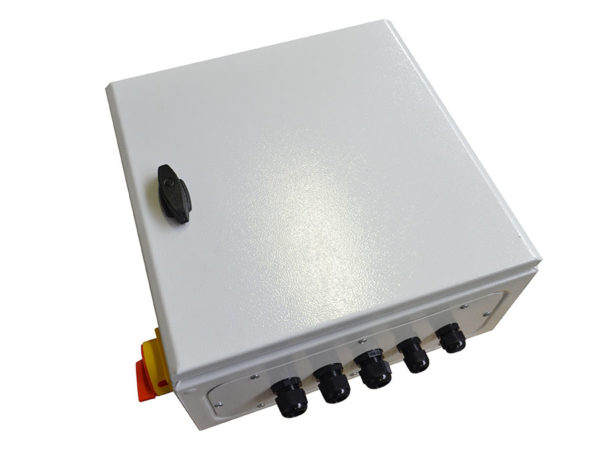

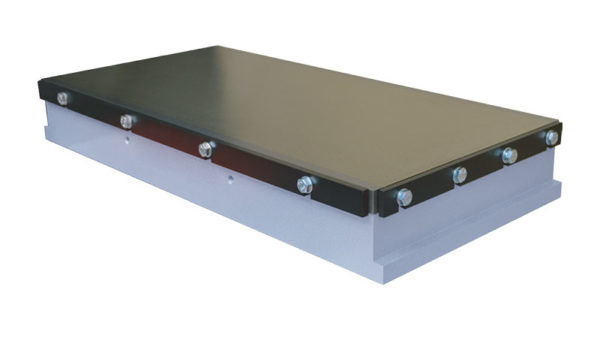

How the ElectroPermanent Chuck Control Unit Works:

The ElectroPermanent Chuck Control Units are designed to magnetize and demagnetize all types of ElectroPermanent magnetic devices depending on its factory settings. The magnetization cycles consist of one or several positive voltage pulses. The demagnetization cycles consist of a specific combination of alternating positive and negative voltage pulses. Note: The work piece material may retain some residual magnetism due to its chemical and magnetic properties.

Options:

MPI offers two variations of the Electromagnet Control Units depending upon output voltage.

- Electromagnet Control Unit 150W

- Electromagnet Control Unit 630W