Description

How the Eco-Flow Magnet Works:

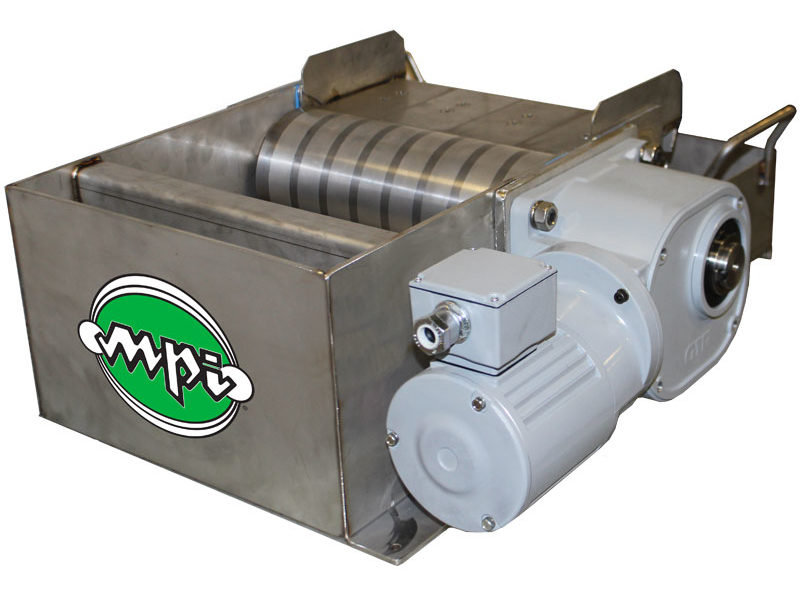

- The Eco-Flow is a continuous cleaning magnetic separator that removes grinding swarf and other contaminants from coolants. It then deposits them directly into a disposal bin, eliminating the need and costs associated with collecting, transporting and dumping waste materials

- As swarf is removed, fluids are fed automatically back into the reservoir tank

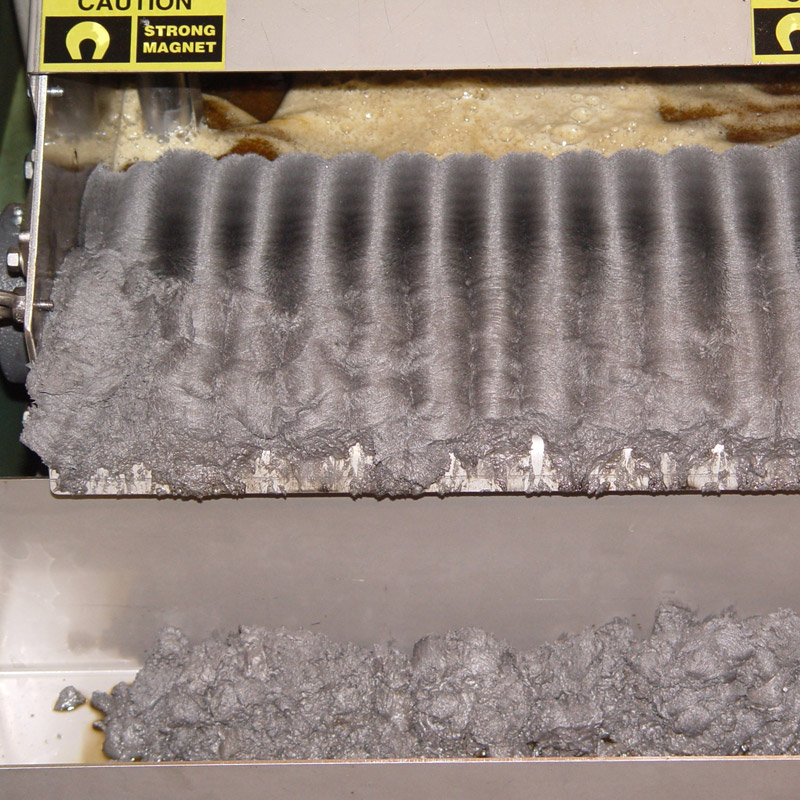

- An extremely dry swarf “cake” is produced

- A drier cake means fewer messy, oily pools around machinery, and improved coolant recovery, reducing consumable costs

- Magnetic technology is green. It substantially reduces both the need to buy costly consumables and the associated downtime required to change paper filters