Description

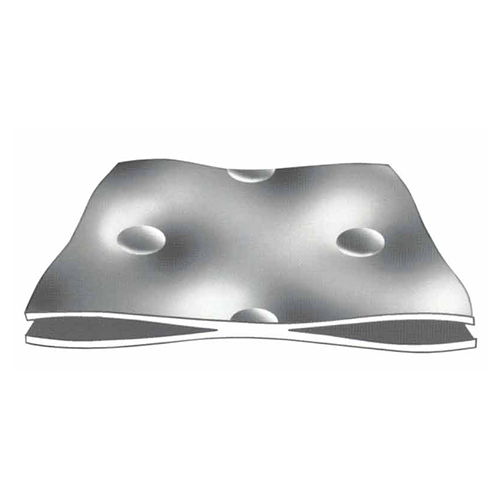

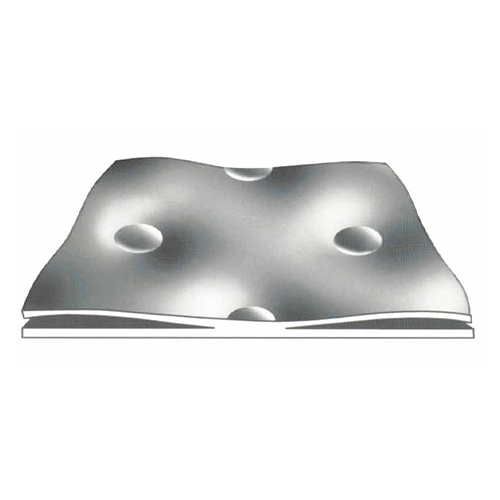

Delta T Thermal Solutions ECONOCOIL® is a very efficient and versatile light-duty plate-type heat exchanger. Its unique construction enables high heat transfer efficiency for heating and cooling, which can be applied to a wide range of applications.

ECONOCOIL® is fabricated from two sheets of metal using a fully computerized welding machine that uses electric roll spot resistance welding. The plate is then hydraulically inflated, forming a variety of flow patterns. Each ECONOCOIL® plate is designed and constructed to match the needs of each application and requirement.

We form in all types of malleable metals – carbon steel, titanium and others.

ECONOCOIL® Applications

- Plating

- Metal Finishing

- Chemical Processing

- Pulp and Paper

- Waste Treatment

- Textiles

- Pharmaceuticals

- Food and Beverage