Patented Spherical-Disc Diffuser-Plate Design

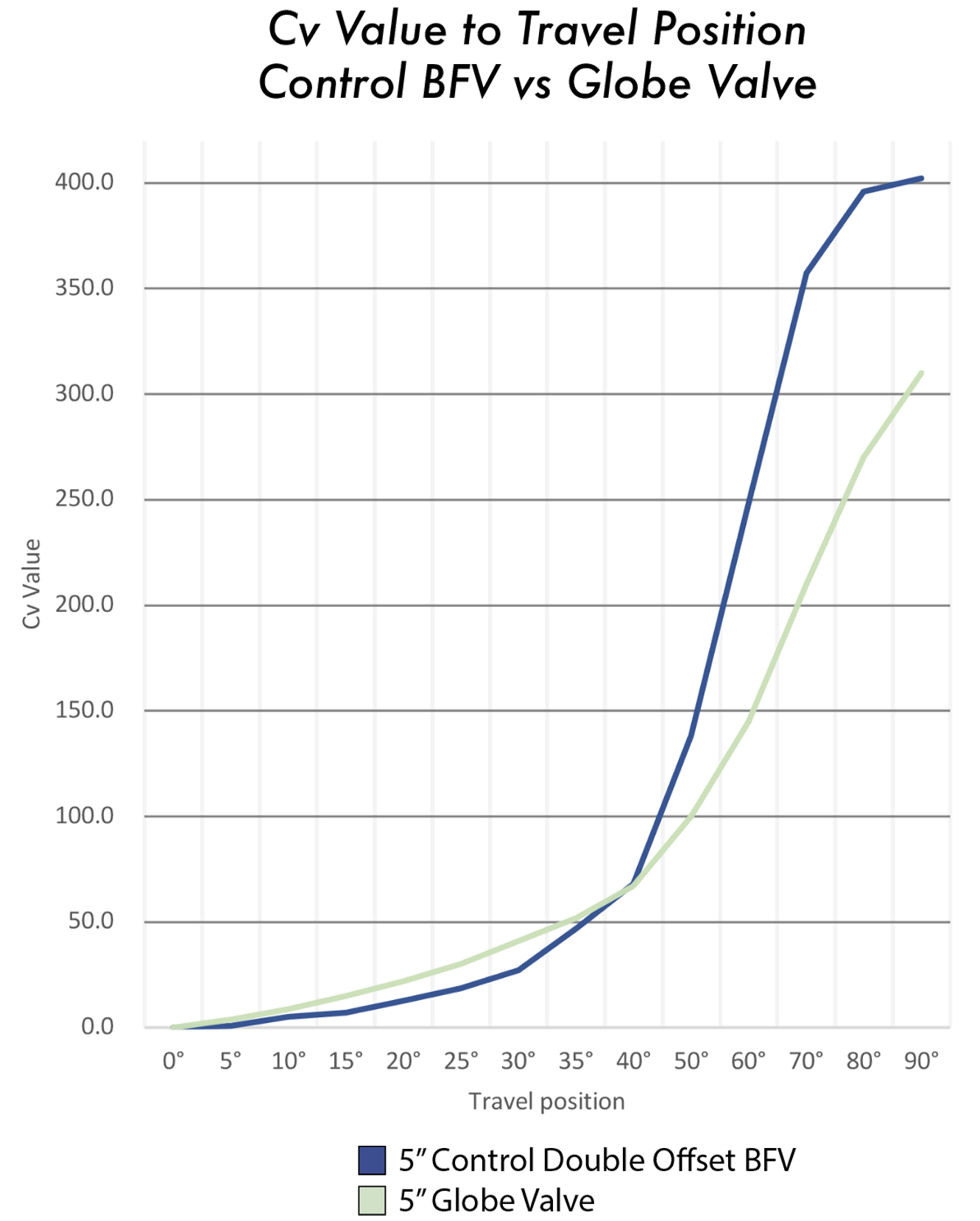

This is NOT just a modified butterfly valve; it is uniquely patented design that overcomes some of the limitations of classic control valves. Compared to the industry standard Globe Valve, this design has improved control at lower flow rates, better range-ability, higher flow capacity, reduced noise and vibration, and all at a lower cost.

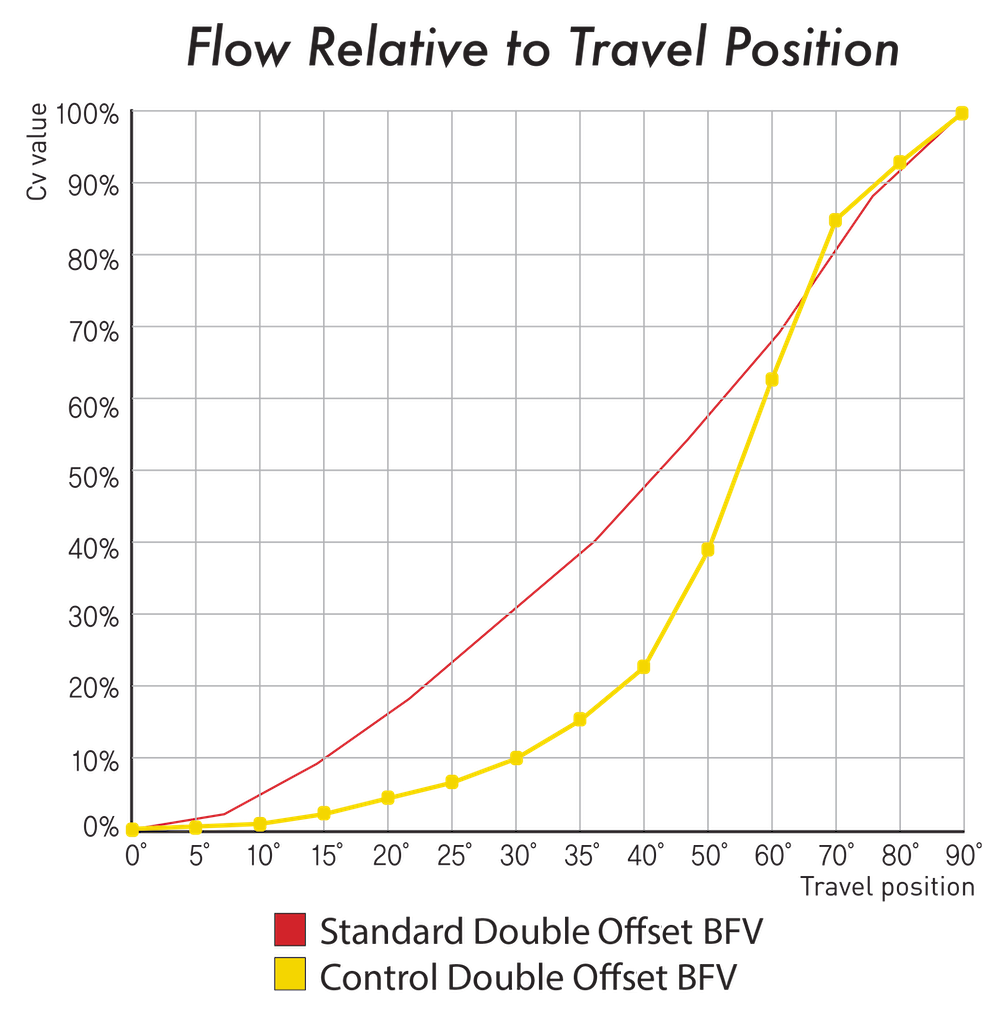

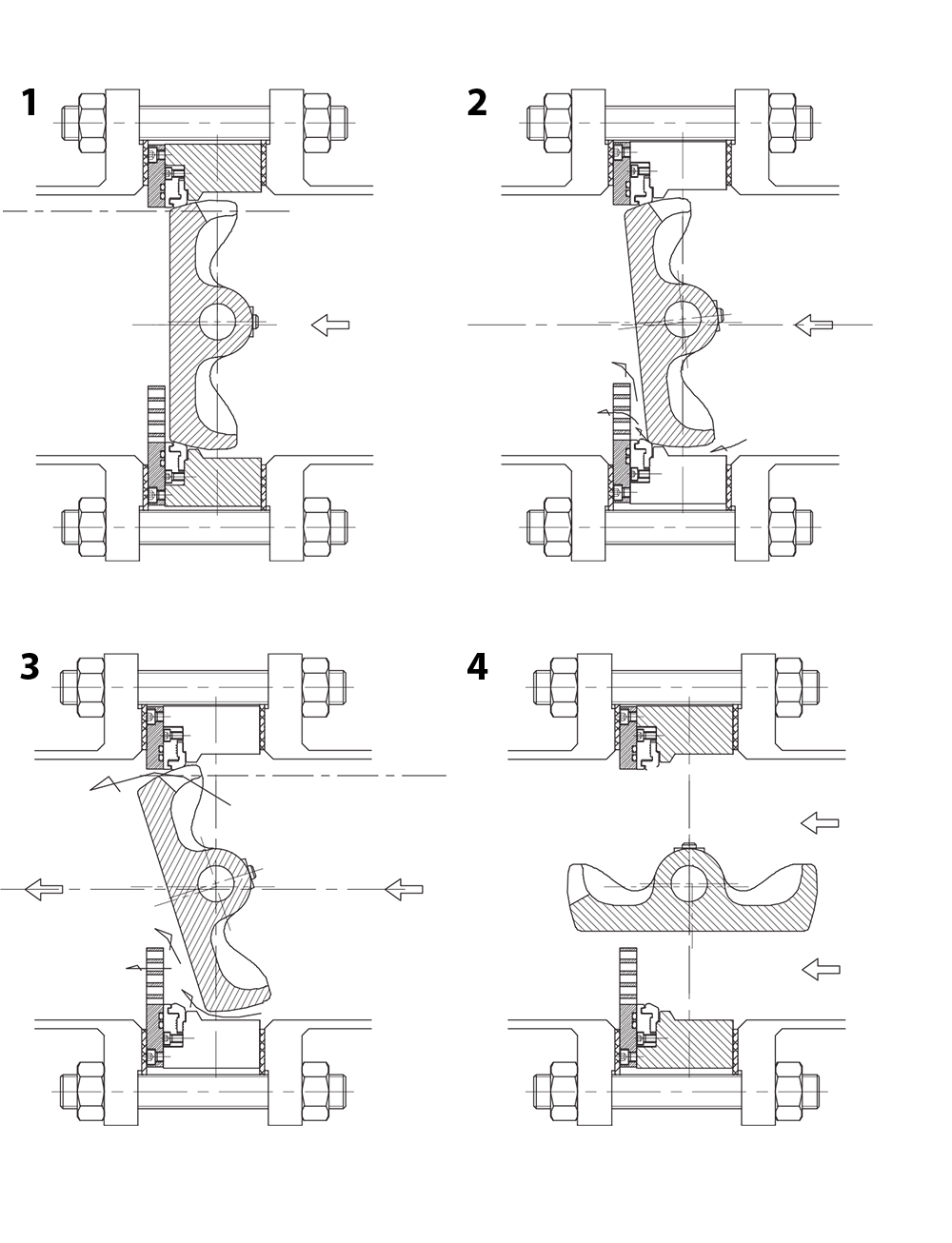

The superiority of this patented design is in the Two Control Phases.

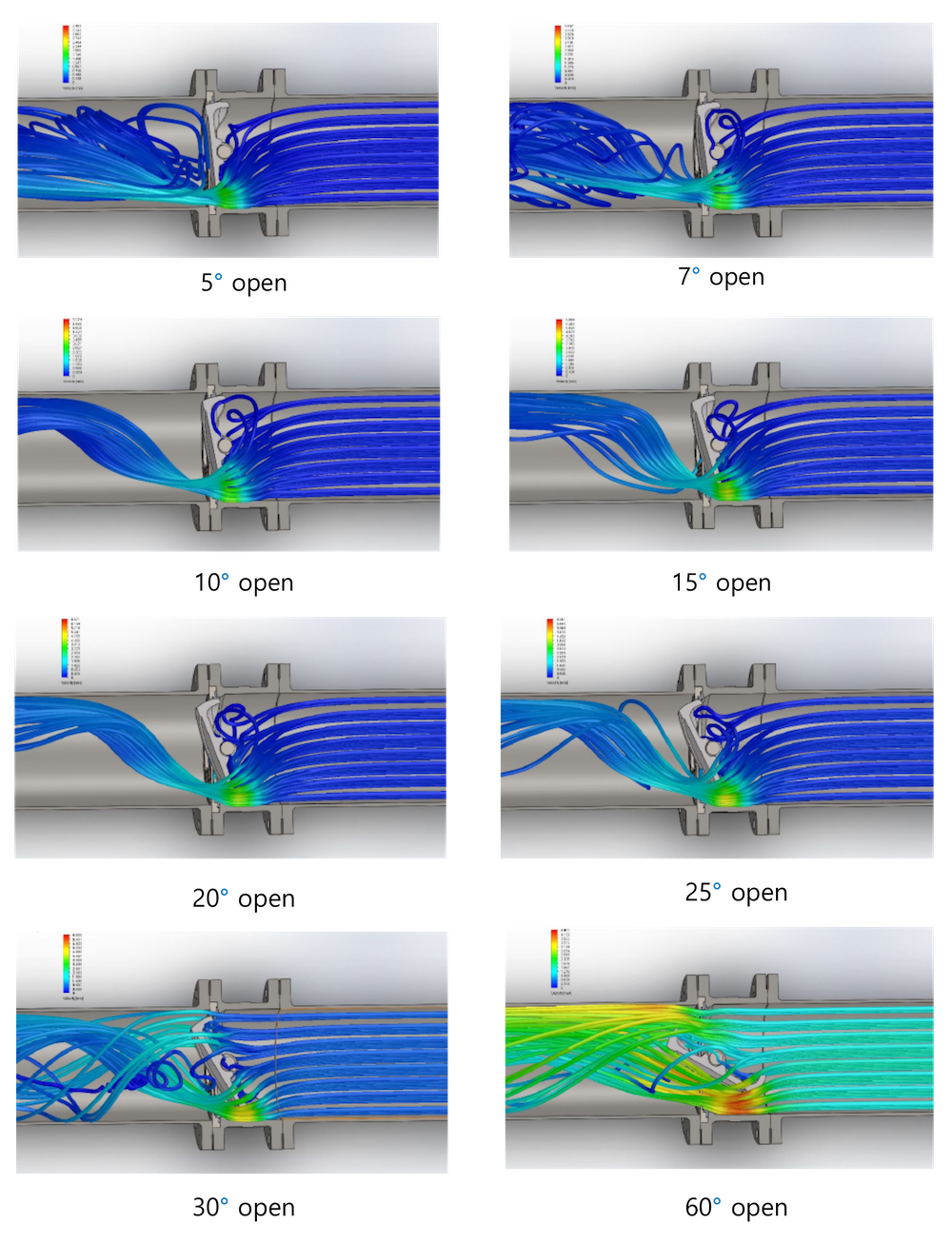

Diffuser is defined as “A device for reducing the velocity and increasing the static pressure of a fluid passing through a system”. Delta T’s unique diffuser plate butterfly valve does that by incorporating a spherical edged disc with the diffuser plate to direct and diffuse the flowstream. This optimizes the ability to control flow and minimizes noise, cavitation and damaging high velocity jets of fluid. In the first 30° of rotation, when pressure drop is the highest, the spherical edged disc constrains the flow, directing it through the diffuser to minimize the potential for damaging flow conditions.