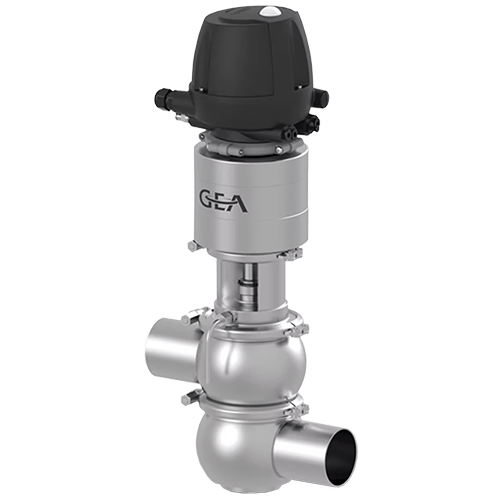

D-tec® Direct Valves

Main Components

Housing

The height of the dead-space-free housing exactly corresponds to the diameter of the connection pipeline and therewith avoids domes and sumps. Numerous housing combinations are available with either clamped or welded seats.

Internal Assembly

The hermetically sealing D-tec® stem diaphragm is the key element of a D-tec® valve. It is characterized by a very long service life, high dimensional stability with temperature resilience and cleanability. D-tec® shut-off valves can be equipped with a soft-sealing (i.e. EPDM) or a hard-sealing (TEFASEP® gold) valve seat seal.

Actuator

The actuator size, which is chosen based on process and installation requirements, contributes to low air and energy consumption. Depending on the valve operation, various actuator options are available and the valve can be ideally adapted to customer requirements. The actuator includes an interface to mount a T.VIS® control top onto the valve and the internal air supply reduces the risk of failures with external hoses.

Lantern

The lantern connects actuator and product-wetted parts and simultaneously prevents the system from heat transfer between these two valve sections. The lantern has an important supporting and clamping function for the D-tec® stem diaphragm and is furthermore designed for a safe and easy visual detection of leakages.

Control & Feedback System

D-tec® divert valves can be equipped with T.VIS® control tops M-15 and A-15. They enable seamless integration of the valves into an automated processing plant.