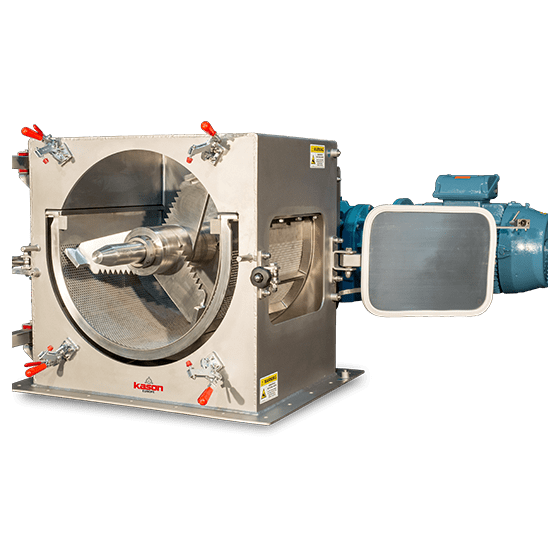

Conical milling for size reduction plays a crucial role in numerous applications. Kason’s cone mills offer a flexible and cost-effective reduction of fatty, heat-sensitive, sticky, moist, or fragile materials.

We manufacture a range of cone mills that can carry out gentle, cost-effective, precise wet and dry milling, pre-milling, preconditioning, granulating, and de-agglomeration applications. All Kason Cone Granulation Mill models provide gentle milling for food, pharmaceutical, powder processing and other similar applications. With a range of different grinding media and tooling options, the cone mills are ideal for businesses that need flexibility as they test different particle sizes.

Product Benefits

Kason’s cone mill size reducer equipment offers a great deal of flexibility, saving time and money with its:

- Interchangeable and diverse grinding media, which can be easily changed

- Operator-friendly design with added safety features

- Particle size distribution offerings from 125 to 250 microns

- Access points for easy and safe cleaning

- Significant reduction in dust generation and product build-up during the milling process

- Low noise and heat generation

Application Data Sheet – Fill Out and Return for Accurate Quote