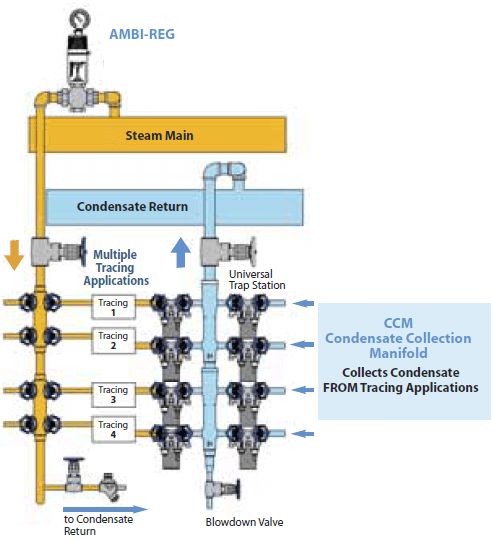

Description

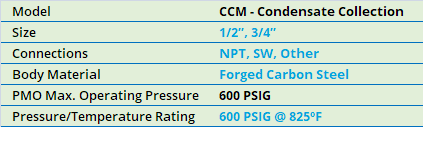

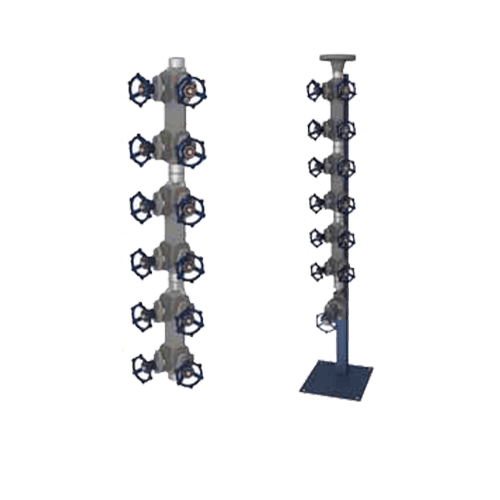

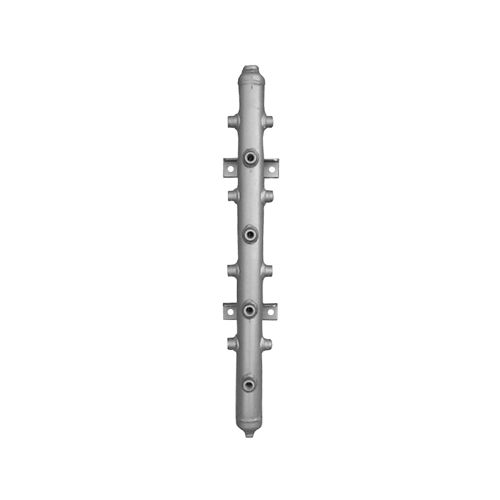

Condensate Collection Manifolds are used for condensate collection FROM the tracing system. Commonly used in chemical and petrochemical facilities as well as in other industrial plants that have multiple tracing applications.

Condensate Collection Manifolds:

- Reduces Installation Costs

- Reduces Maintenance Costs

- Organizes Piping

- Streamlines Your Process