Description

Applications:

- Overflow Protection

- Material Outages

- Plugged Chutes

- Process Control

- Conveyor Overload

Downloads:

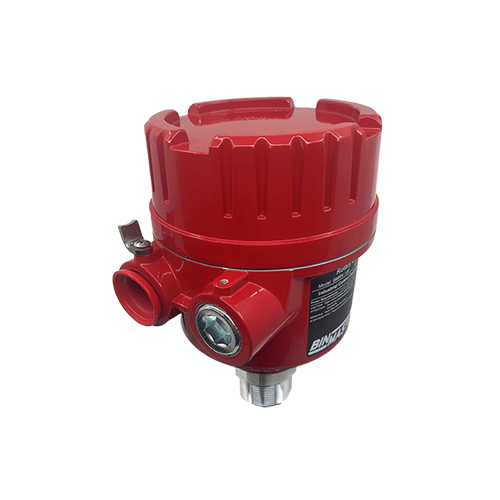

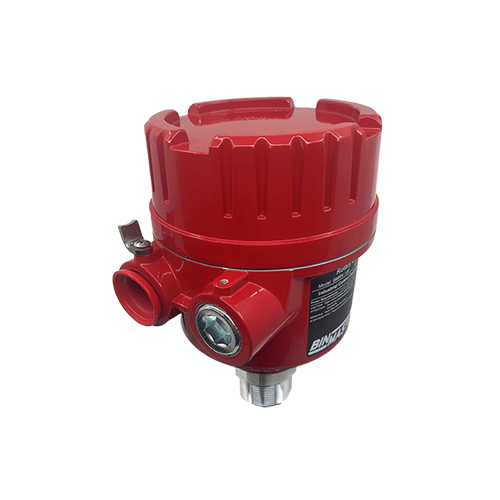

The new BinMaster BMRX-100 rotary level indicator is an electromechanical device used in solids and powders to prevent bin overfills, dry runs, or to shut off a process. The BMRX-100 has no printed circuit board, so it’s impervious to moisture and vibration found in many tough processing environments.

By alerting to full and empty vessel conditions, it prevents waste and saves time when handling bulk materials stored in bins and silos. It’s designed for materials with a bulk density of 2 lb. to over 100 lb./cu. ft. for use in ordinary storage and processing conditions.

The new red enclosure can be rotated once installed. This unique feature makes it easy to ensure conduit entries are always pointed toward the ground, mitigating the risk of moisture damaging internal components. New wire guides ensure wires don’t get stuck as you push them through conduit entries.

Couplers and paddles sold separately.

Rotary Paddle Switch: Point Level for Solids

The BMRX-100 is an affordable paddle-style level switch for point level alerts in solids and powders with a bulk density of 2 lb. to over 100 lb./cu. ft.

Want to prevent overfilling bins? Eliminate dry runs in processing operations?

Wire the BMRX-100 rotary to a light or horn to alert to high or empty levels. Use the relay to start or stop a process such as augers or conveyors belts.

Simple, electromechanical measurement for ordinary storage and processing operations.

Agriculture. Bins containing grain, seed, feed, fertilizer, or bulk ingredients.

Construction. Concrete and cement batch plants, silos of roofing granules.

Mining. Sand, gravel, aggregate, and coal storage, and surge bins.

Plastics. Detect level of plastics pellets in silos or hoppers.

Accessories for the BMRX-100.

Paddles. Select from 19 different styles for light, medium, and heavy bulk solid materials. Collapsible paddles for installation without entering the vessel.

Mounting plates. Carbon and stainless-steel options in 0°, 10°, 20° and 30° angles for top mounting on sloped roofs.

Point level alarm panel. Provides vessel level conditions via a blinking light and audible alarm with up to 24 level indicator stations.

Quick disconnect. Replaces hard wiring to make it simple to install and remove the rotary for cleaning, maintenance, or replacement.

Adjustable top mount. Change the high-level threshold simply using an adjustable coupling that can be moved up and down a 72” shaft.

Downloads: