Description

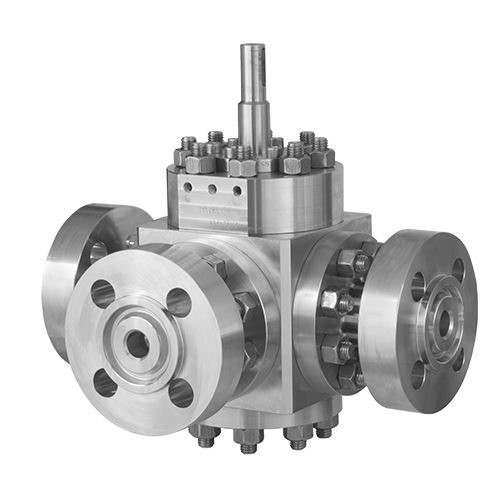

The Sesto double block and bleed ball valves’ design is engineered for critical service. It can easily be customized for nearly any application. Achieve double block and double isolation by integrating two ball valves into one body. This design minimizes leak paths and reduces footprint.

Multiple valves can potentially be replaced with a single unit. They can include one or more bleed valves configured to specific requirements. Both ball valves can be operated independently. They can be used with manual or powered operators. Safety lockouts are available.

The design also allows for integrity check of seals. This is important for when fail-proof isolation is critical and leakage could have catastrophic consequences. Simplify piping requirements while increasing safety and reliability.

Precision Machined Forged Body

The forged body eliminates the possibility of leakage due to poor castings. Precision finish machining keeps tight tolerances. This ensures secure assembly for high pressure, critical applications.

Ball/Seat Lapping

Lapping seats to the ball ensures tight tolerances. This improves shut-off sealing capability while lowering torque requirements.

Application Specific Testing Protocol

Built upon proven API 598, API 6D, and MSS-SP-61 testing standards and customize our testing protocols. This simulates actual service pressure conditions. This process guarantees valve performance before field installation.

Customizable Design

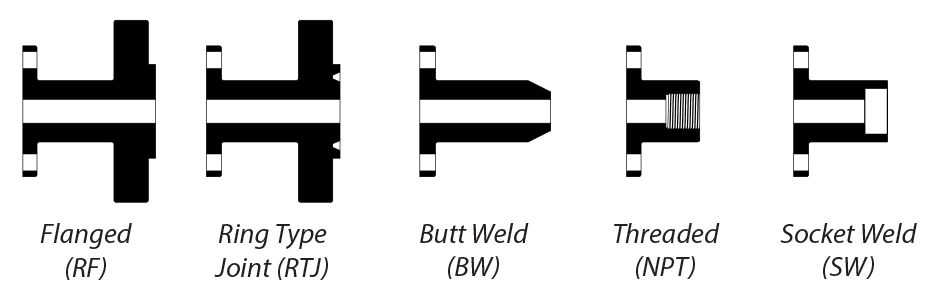

The design is highly customizable. End connections, face-to-face lengths, and other features can be modified to suit application requirements.

Critical Shutdown Valves

Sesto Valves are designed and manufactured to internationally recognized standards including but not limited to the following:

- Design: API 6D, API 608

- Fire Testing: API 607, API 6FA, BS 6755 Part II

- Testing: API 6A, API 598, API 17D, ISO 5208, BS 6755 Part I

- Marking: API 6A, MSS-SP-25, PED

- Certifications: API607, SIL, NACE, MR0175, PED, Fugitive Emissions

Partial List of Applications

- Oil & Gas Pipelines

- Refineries and Petrochemical Plants

- Power Generation

- Gas and Coal Fired Turbines

- Gas Purge Credit Systems

- Floating Production Storage & Offloading

- Offshore Platforms

- Emergency Shut Down Valves

- Chemical Injection

- Gas Measurement Systems