Description

Main Components

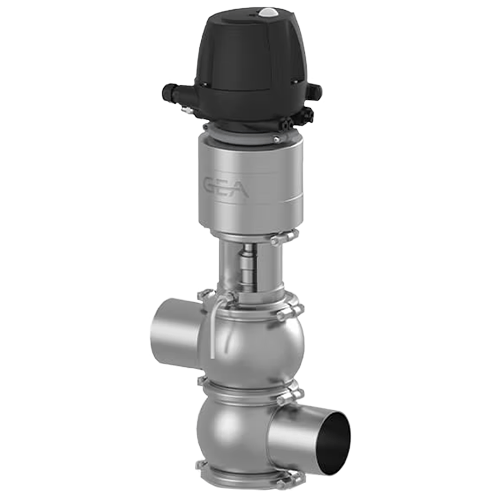

- Housing: The single-part housing with two chambers designed specifically for this control valve ensures that no mechanical interfaces outwards can endanger product safety on the negative pressure side, like it can occure at flash vessel applications. They are available with either two or three port connections. The valves are produced with standard butt-weld connections by default. Mixed port connection sizes, a divisible design for Internal Assemblies with an additional valve seat seal as well as various aseptic pipe connections are available upon request.

- Internal Assembly: The internal assembly is designed without an additional valve seat seal by default. It includes a hemispheric control cone to enable smooth operation in a process and includes only one product-wetted seal. Designs with an additional valve seat seal are available upon request.

- Actuator: The standard version of the pneumatic actuator is designed as air-closing / spring-opening and results in a normally open failsafe position for inverted control valves.

- Clamp: Due to its solid construction, the GEA clamp enables a pressure stable and safe connection of the main components. The special design with three segments allows a service-friendly handling of the component, even under tight space conditions.

- Positioner/Process Controller: Aseptic inverted control valves can be equipped with three different types of positioners. The closed centralized positioner (GRZ) is used by default and can be exchanged with either an open centralized positioner (ORZ) or a closed decentralized system (GRD). Depending on process requirements, it is also possible to apply a process controller instead of a positioner.