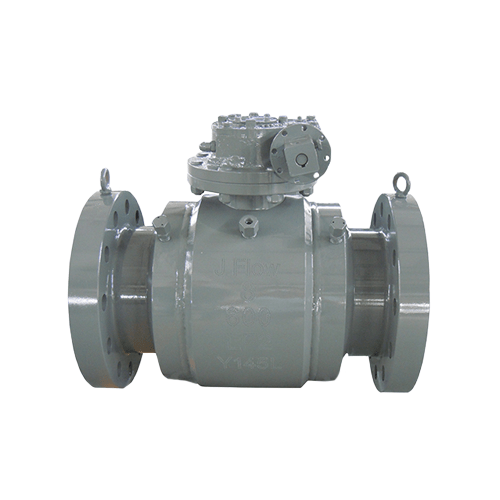

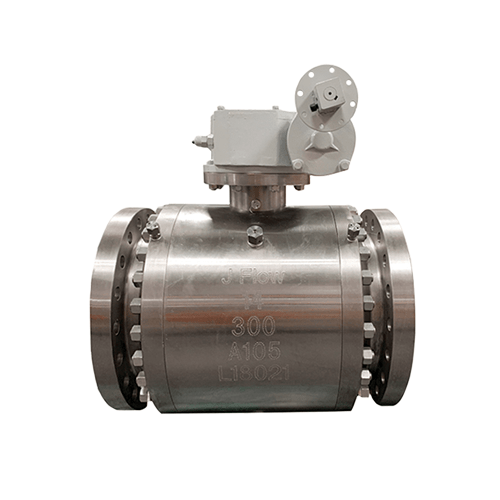

Description

SIZES

- 2″ – 60″

BODY MATERIAL

- 304

- WCB

- 316

- LCB

- LF2

- F316

- A105

SEAT MATERIALS

- Nylon

- RPTFE

- TFM

- Metal seated

- PEEK

- Carbon PEEK

- Tungsten Carbide

- Stellite

- Devlon

- PORT

- Full port

- Reduced port

END CONNECTIONS

- NPT

- Socket Weld

- Butt weld

- ANSI 150-2500

TEMPERATURE RANGE

- -50°F to +1000°F

OVERVIEW

J Flow Ball Valve Product Overview

J Flow Automation Capabilities Overview