Description

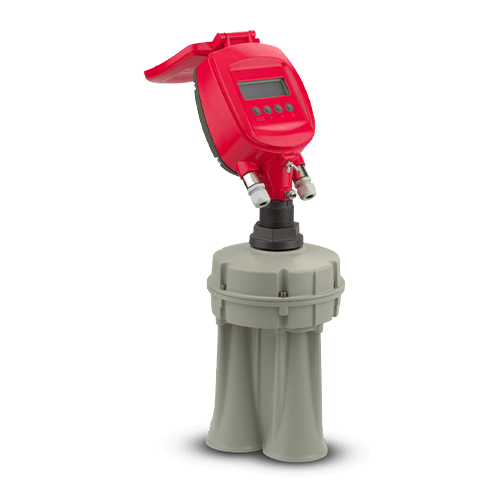

3DLevelScanner: Multiple Point Measurement for Accurate Volume

Advanced acoustics technology measures material topography in dusty environments for effective non-contact volume measurement.

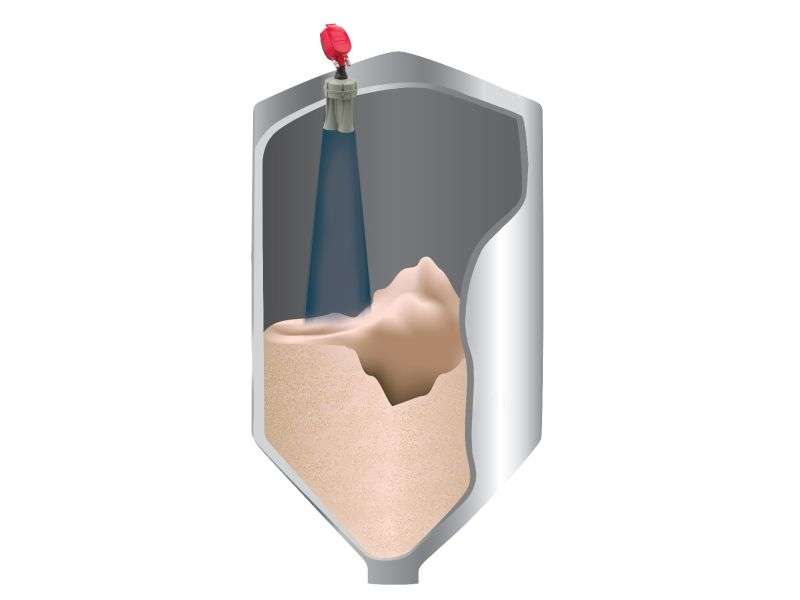

Need volume accuracy in irregularly piled materials? 3D visualization to detect sidewall buildup?

Advanced acoustics-based technology is a proven performer in dusty powders and bulk solids.

5 Ways 3D is different:

- Most level sensors only measure a single point

- Optional 3D visualization of material topography

- Detects cone up, cone down, and sidewall buildup

- Provides minimum, maximum, and average distances

- Accounts for surface irregularities for accurate bin volume

3D excels in unevenly piled material:

- Grain, seed, feed, and food processing

- Ethanol, bioenergy, and power plants

- Aggregates and cement

- Mining and metals

- Chemical processing and plastics manufacturing

- Pulp, paper, and wood pellets