Description

Multiple-Scanner System: Measure Volume in Big Bins

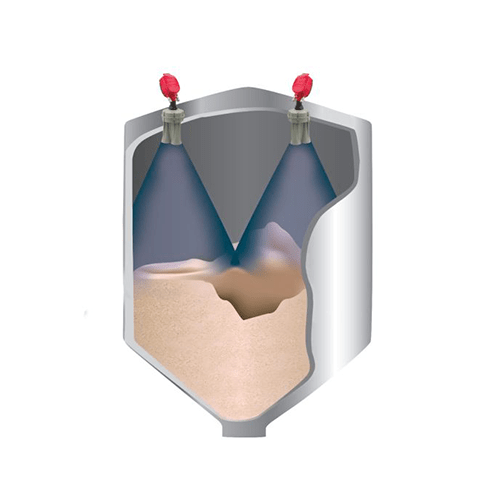

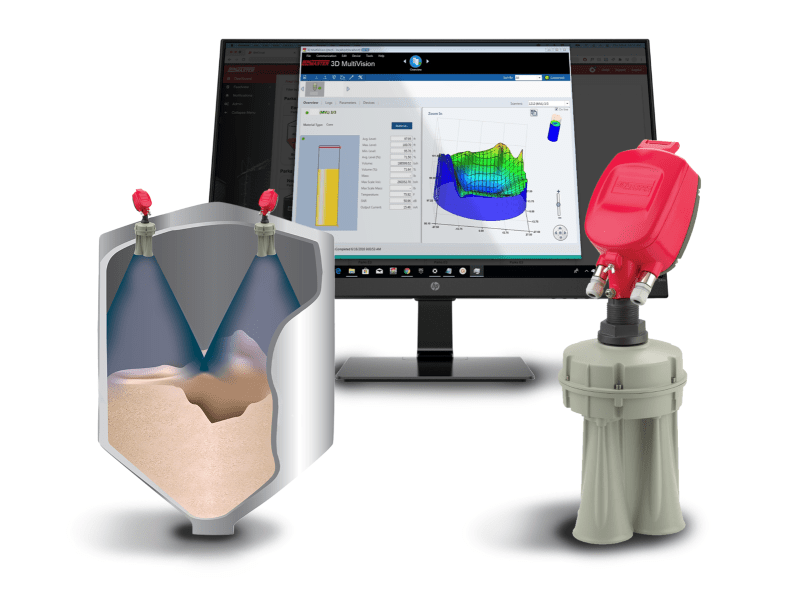

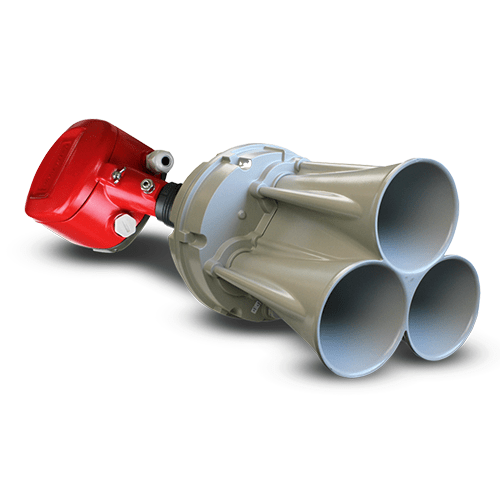

The MVL system integrates multiple-point measurement data from two or more 3D scanners to cover a very wide surface area to estimate inventory volume in large diameter bins.

Need to measure volume in large diameter bins? Would 3D visualization help you better manage bulk materials?

Multiple point measurement from multiple scanners is synchronized to provide a cohesive view of irregularly piled material.

What you get with 3D MVL:

- Significantly increased inventory accuracy in very large, wide silos

- A 3D visual that shows sidewall buildup, peaks, and valleys of material

- Software to estimate volume and provides minimum, maximum and average distances

- Continually updated information and alerts to optimize material management

3D MVL systems are popular in:

- Grain silos including 105s or million-bushel bins

- Large, covered grain storage facilities

- Ethanol facilities with large bins of corn or DDGS

- Bins or bunkers of coal, fly ash, or limestone at power plants

- Large clinker, cement, or limestone silos at cement manufacturing plants

- Wide soybean silos used in biodiesel production

- Animal feed stored in large silos, bunkers, or warehouses

- Bins storing fertilizer or sand

- Mining operations with silos or stockpiles of limestone or ores

- Large domes of bulk raw sugar

- Ports with large storage silos and domes

- Covered domes or bins storing salt