Plate and Frame Leak Detection Testing with NEW Predictive & Non-Intrusive Service

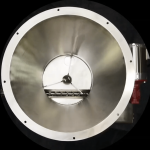

In sanitary processing, the integrity of your Plate & Frame Heat Exchanger is everything. Even the smallest leak can cause major problems: from costly contamination issues to unplanned downtime. WCR is proud to introduce a NEW non-destructive plate and frame leak detection testing service using hydrogen gas. This is a cutting-edge, efficient, and predictive solution tailored specifically for the dairy, food, and beverage industries.

A Smarter, Predictive Approach to Leak Detection

Unlike traditional dye testing, which requires unit disassembly and often detects problems only after contamination occurs, WCR’s hydrogen-based testing is non-invasive, quick, and predictive. This test detects leaks as small as 30 microns using a safe 10% hydrogen gas/air mixture, identifying issues before fluids cross and cause damage.

This proactive approach means:

- You can schedule repairs during planned downtime

- Avoid emergency shutdowns

- Maintain compliance with regulatory standards

- Protect product quality and brand reputation

Non-Destructive, No Disassembly Required

One of the biggest advantages of WCR’s hydrogen leak detection is that there’s no need to disassemble the unit. This minimizes labor and downtime. Your maintenance team can stay focused on other tasks, and your production schedule remains largely unaffected.

The test takes just 15–30 minutes per section, making it ideal for busy facilities where every minute counts.

Ideal for Sanitary Applications

This service is specifically designed for clean, sanitary environments such as:

- Dairy processing

- Food production

- Beverage and brewing facilities

However, this method is not suitable for “dirty” applications, such as vegetable oil processing. But for facilities using multi-pass units, especially common in dairy, this test proves unmatched precision and reliability.

Detailed, Automated Reporting

Every test comes with a comprehensive automated report, showing leak levels by section and pressure (tested at 1, 2, and 4 bar). In addition to internal leak detection, the system also uses a sniffer probe to find external leaks. The testing equipment is calibrated on-site before every use, ensuring accurate and repeatable results.

Regulatory Compliance and New Business Opportunities

Most facilities require annual leak detection testing for compliance. With WCR’s new hydrogen-based method, facilities can meet those requirements more efficiently and reliably than ever before. The goal is assisting the sanitary industry by helping processors stay compliant, safe, and ahead of maintenance problems.

Get Started Today

WCR brings decades of heat exchanger experience to every test. The trained technicians specialize in PHE performance, diagnostics, and maintenance. Get more than just data; get expert guidance and actionable insights.

Ready to Schedule Your Leak Detection? Don’t wait for leaks to cost you. Schedule predictive plate and frame leak detection testing with WCR today, and take the guesswork out of Plate & Frame Heat Exchanger maintenance. Contact Apex now to learn more or request a quote.