Features and Benefits of Meyer Pneumatic Screw Pumps

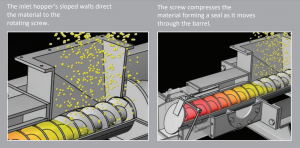

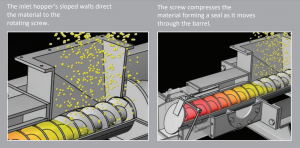

The Meyer Pneumatic Screw Pump is an airlock designed to feed dry pulverized material from a gravity feed hopper into a pneumatic conveying line by using a screw auger. It is engineered to perform in applications that exceed the abilities of typical dilute phase rotary feeders. It is an ideal replacement for airlock feeders that have failed to handle fine, abrasive or friable materials.

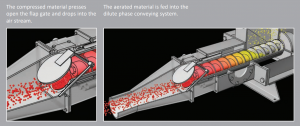

Unlike rotary airlocks, which require tight clearances to seal against the conveying air, the Screw Pump utilizes the conveyed material to form a seal during operation and an integral flap gate prevents blowback during system startup or when running empty. Compared to double flap valves, which batch material as the gates cycle open and closed, the Screw Pump provides a continuous flow of material into the conveying air stream. It is a dust free feeder and significantly reduces abrasive wear; minimizing maintenance and unplanned, costly downtime.

Features:

- Heavy Steel Channel Frame

- Quad Seal

- Integral check valve

- Hard coated shaft assembly

- Low inlet hopper height

- Three conveying air inlet points

- No product contact with bearings

- Temperatures up to 450°F

- Low conveying pressure -4 to 12 PSI

- Oversize Bearings

Benefits:

- Increased conveying rates with less air

- No blowback, even when running empty

- Increased resistance to abrasive materials

- Low Profile

- Fully warranted and guaranteed

- Longer bearing life/fewer system shutdowns

- Reduced operating and maintenance costs

| Model | CFM | Line Size |

|---|---|---|

| 44 | 6 | 4 |

| 45 | 11 | 5 |

| 66 | 22 | 6 |

| 67 | 34 | 8 |

| 68 | 45 | 10 |

Downloads:

The Meyer Pneumatic Screw Pumps are in stock and ready to ship to you now. Contact Apex today!