Benefits of Energy Savings – How to Improve Your Plant’s Efficiency

Energy savings within a plant is something all industrial businesses need to consider. Here are 5 simple reasons why you should consider energy savings when analyzing your plant’s efficiency:

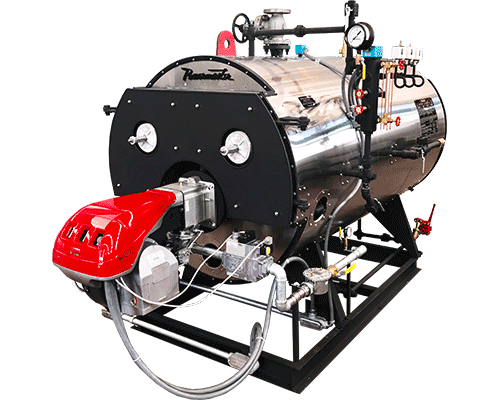

- Cost savings: Energy is often one of the biggest expenses for industrial plants. By reducing energy consumption, a plant can save a significant amount of money on its energy bills, which can translate to higher profits and reinvestment in the business. This can be done by simply updating old equipment. This may seem like a large investment at first, but many states offer reimbursements for implementing energy efficient equipment. You will also save money on energy every minute the machine is in operation – this adds up quickly. We have seen multi-million-dollar boiler system projects pay for themselves in only 5 years on energy savings alone!

- Environmental benefits: Reducing energy consumption can also have positive environmental impacts, such as reducing greenhouse gas emissions and minimizing the plant’s overall carbon footprint. This is also something many consumers are searching for when choosing a brand so your reputation can become more receptive as well.

- Increased competitiveness: As energy costs continue to rise, energy-efficient industrial plants can become more competitive in the marketplace, as they are better able to control their operating costs and offer more competitive pricing to customers.

- Improved equipment reliability: Energy-efficient equipment often operates more reliably and requires less maintenance than older, less efficient equipment. Utilizing new energy-efficient equipment can lead to lower maintenance costs, increased employee productivity, and reduced downtime. Contact Apex and our team will evaluate your entire process for you and offer improvements.

- Regulatory compliance: Many countries and jurisdictions have regulations in place that require industrial plants to reduce their energy consumption and emissions. By implementing energy-efficient measures, a plant can comply with these regulations and avoid penalties or fines. This allows you to save more money and reduce stress among your employees.

Not sure where to start? No problem.

- One thing you can do on your own is analyze your internal processes within your employees. We can help with the equipment, but we can’t be there to make sure your team is operating properly. Walk your process from start to finish and watch how your employees and software communicate. Check for redundancies and improvements. Identifying, improvising, and monitoring problems can enhance productivity and efficiency.

- Review training with your employees. Again and again. There is no downside to reinstating how you want your employees to operate within your process. Showing your employees the entire process from start to finish and showing exactly where they fit into that process gives them a better understanding of their position. Training can also improve employee safety and your company’s reputation. Ensure that you also allow your employees a platform to present their own ideas for improvements. They know their jobs best, after all.

- You’d be surprised how much energy is used just lighting your plant. Switching all of your lights to LED can significantly reduce your energy consumption. (Many states offer partial reimbursement if you replace every light in your building with LEDs!) Save even more by implementing light sensors that turn off or dim lights when spaces are empty.

- Regular maintenance is just as important as regular employee training. Ensure that your equipment is operating safely and efficiently by performing regular maintenance across your entire process. Regular equipment maintenance can avoid any costly future repairs or potential employee injuries. Our team can assist with certain equipment maintenance – check our Services Page for more information.

- If your employees are in the best condition, your process can fall flat if your equipment is not. Apex Industrial Solutions will evaluate your plant’s process equipment from start to finish. We supply everything you need from top to bottom and have employees that specialize in each area of your plant. Whether you are looking for an entire plant overhaul or just a simple steam trap survey, contact us to schedule your visit today!

Recommended Posts