The Secret of Energy Recovery

Boilers and steam systems are at the heart of most industries. They are a critical utility which needs to be professionally designed to optimize energy consumption. If you are one of many facilities that use a boiler or steam system, you already have 90% of what you need to discover the secret of energy recovery. With a simple bypass, you can harvest your unused thermal energy. Read on to learn more!

The Secret of Energy Recovery

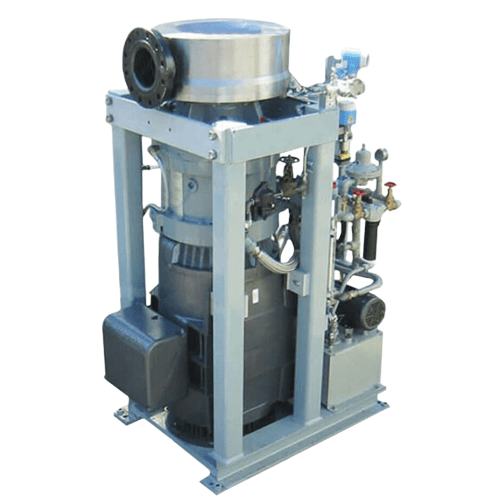

NLine Turbines have the ability to generate electricity from your steam system’s pressure reducing valve. The Microsteam Turbine (MST) is a compact energy recovery system that utilizes pressure and flow energy that would otherwise be wasted in your steam system’s PRV. The MST harvests all of that energy and converts it into usable electricity. Typical applications include:

- Hospitals

- Schools & Universities

- Food & Beverage

- Dairy

- Breweries & Distilleries

- Ag Processing

- Industrial Manufacturing

Will Your System Benefit from an NLine Microsteam Turbine?

The NLine Turbine allows you to turn wasted energy into savings. Assuming you have a pressure drop of 200 to 125 PSIG (75 PSI) at a steam flow of 20,000 lbs/hr in your current steam system, you can generate 2.3MM kWh a year and reduce CO2 by 1,797 tons! But will your current system benefit from an NLine Turbine? If any of the following descriptions apply to your steam system, you will benefit from an NLine Turbine:

- High pressure to low pressure systems with a 65 PSI minimum pressure drop

- High pressure to low pressure systems with high steam flow rates (40,000 PPH or greater)

- Systems that operate 24/7 or close to it

- Biomass energy systems

Get Started; It’s Simpler Than You’d Expect

Steam Tie-In

- The only down-time required is for installation of isolation valves on high- and low-pressure headers. The majority of the installation is completed while the plant is in operation so you can keep operations on schedule.

Electrical Tie-In

- Spare compartment on existing MCC, 500A minimum breaker.

- Back feed to 480V distribution transformer.

Controls

- Seamless integration into existing plant SCADA system.

- Choice of communication protocols (ethernet, Modbus, etc.)

Power

- Synchronous or Induction Generator

- Create a microgrid for plant resiliency

Maintenance

- NLine and O&M schedule – annual service plus detailed turbine inspection every 5th year

- Maintenance agreement renewed every 5 years

Financing Available

- Tax credits, grants, and incentives

- NLine Energy, Inc. arranged construction financing/lease purchase

- NLine Energy, Inc. Power Purchase Agreement (PPA) – Call for more information

- PACE Financing available

Get Started! Fill out the form below and our team will contact you soon