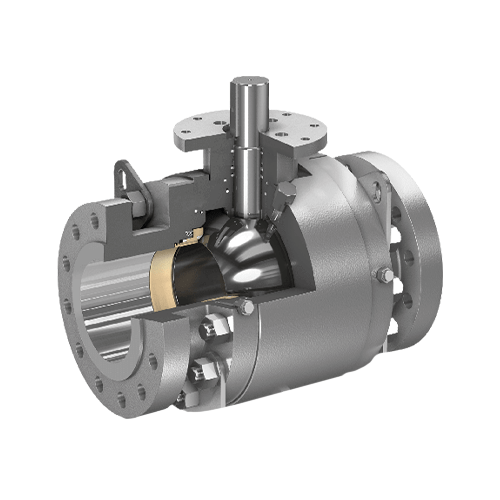

Description

Size Range: 2″ to 12″ (DN50 – DN300)

Pressure Range: Class 2500

Temperature Ratings: -76°F to 1,000°F

Design Features

- 3-piece robust, forged valve

- Double block & bleed

- Blowout-proof robust stem design

- Bi-directional as standard

- API 6D certified (API monogram #6D-1278)

- Fire safe designed to API 6FA, API 607, ISO 10497

- Comply with NACE MR0175/ISO 15156

- Corrosion resistant low friction bearings

- Double Piston Effect or Single Piston Effect seat design

- Mixed SPE and DPE seats design also available

- Integral top-works direct mounting pad to ISO 5211

- 6” and larger valves are equipped with lifting lugs

- 8” and larger valves can be equipped with vent and drain valves (Optional)

- Antistatic grounding between ball, stem & body