Description

Construction

- Color/Cover: 1151GGP Royal Blue/Double PVC Coated Nylon, Abrasion, UV and Ozone Resistant; 3161PGP Grey/Double PVC Coated Nylon, Abrasion, UV and Ozone Resistant; 3164PSP Grey Yellow Stripe/Double PVC Coated Nylon, Abrasion, UV and Ozone Resistant

- Inner Wire: 1151GGP Galvanized Steel; 3161PGP, 3164PSP Black Polypropylene Coated Steel

- Inner Lining: High Grade Polypropylene

- Carcass: Polypropylene Fabrics, Films and Polypropylene/and Seamless Tubes

- Outer Wire: 1151GGP, 3161PGP Galvanized Steel; 3164PSP T316 Stainless Steel

- Logo: MarineMaster®

Physical Properties

- Temperature Range: -22°F to +212°F (-30°C to +100°C)

- Maximum Elongation: ≤10% on test pressure

- Vacuum Range: 26 inHg (660 mmHg), 0.9 bar

- Electrical Properties: Electrically Conductive; ≤1.0 ohm/m for size 2″

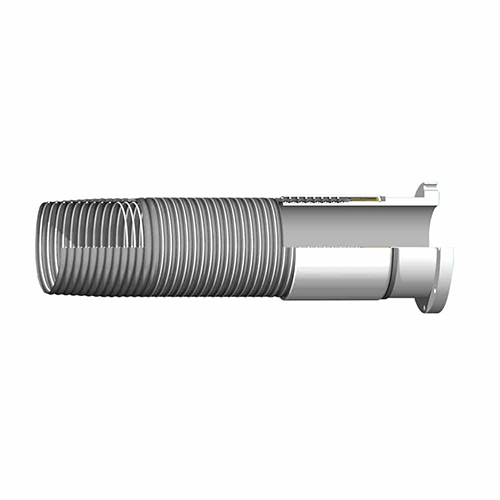

End Fittings

Specially designed end fittings have been developed for use with Willcox Composite hoses that have a unique leak-proof sealing face and specially machined helical spiral shank which engages into the corresponding internal helix wire when secured into the hose by either crimping or swaging the external ferrules.