Waste Heat Boiler Economizer

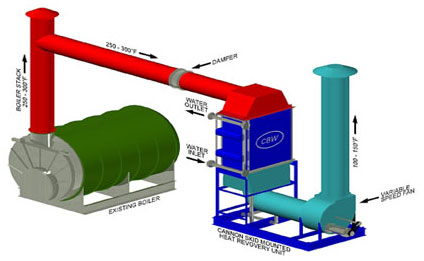

Many times an economizer or waste heat recovery unit just won’t fit into a customer’s existing equipment, due to space or operating limitations. This is where an On-Demand Boiler Economizer will work best.

The On-Demand boiler economizer removes waste heat from the flue gas, similar to the rest of our heat recovery line, but has some unique differences Our on-demand economizer operates only when your system needs hot water and is capable of offering a return on investment in less than a year, depending upon your current system. The systems runs the fan and pump only when heat is available and hot water is needed.

This waste heat recovery system is Invisible to boiler exhaust, eliminating backpressure or condensation concerns and can easily be inspected and repaired if necessary.

Once the waste heat recovery system is optimized for your operation is automatically provides maximum heat recovery and may boost boiler efficiency to over 90%

- Sized for water stream (not flue gas) flow

- Fan and pump run only when heat is available AND hot water is needed

- Automated so can be optimized

- Invisible to boiler exhaust, no backpressure or condensation concerns

Application Datasheet – Fill Out and Return for Accurate Quote