Description

Helically Wound Vs. Bare Pipe Coils

With both bare pipe and helically wound coils as options, how do you choose? Your decision relies on a variety of factors including the application, material to be heated, ambient temperature, preference, and budget. We can help you determine the best fit for your operation.

Benefits of Bare Pipe Tank Heating Coils:

- Bare tank coils are often a better option for highly viscous products, especially where fouling may be a concern.

- Stainless steel bare tank coils can be used in a variety of food, beverage, and other sanitary industries.

- For smaller applications and processes, bare tank coils are often less of an investment.

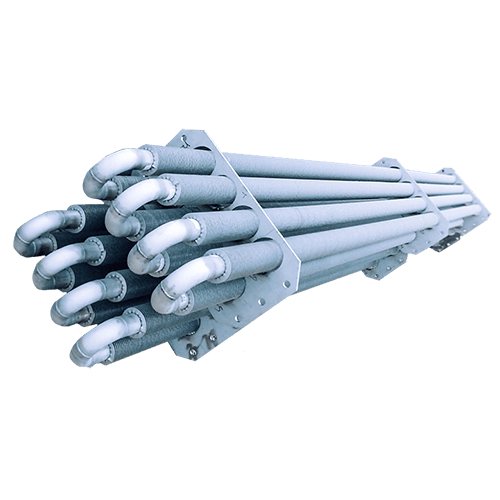

Benefits of Helically Wound Finned Tank Heating Coils:

- Finned tank coils are highly efficient with up to 12x greater surface area than bare pipe coils.

- Greater heat transfer means significantly less pipe is needed to heat the tank, saving money and installation time.

- The larger the application, the better the efficiency when it comes to finned tank coils.

Whichever you choose, be assured that our coils are built with quality and longevity in mind.