Description

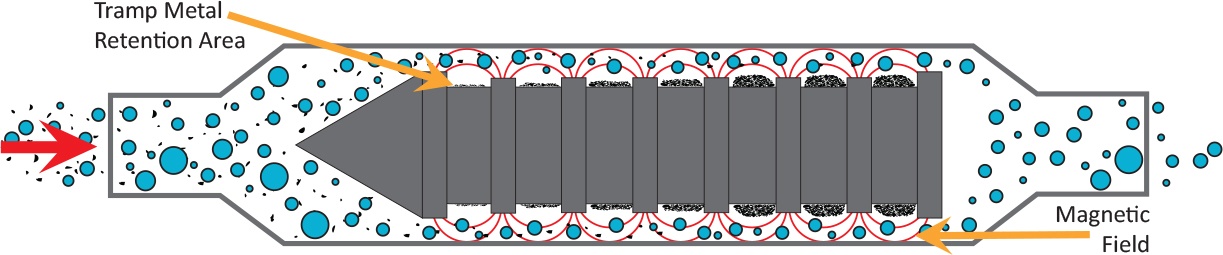

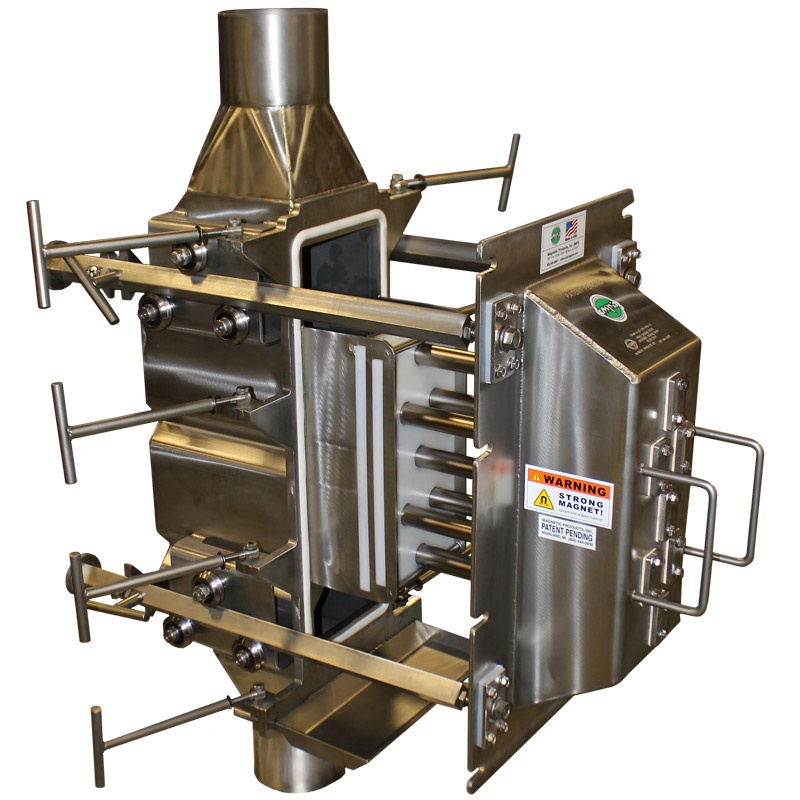

How Pneumatic Line Magnets Work:

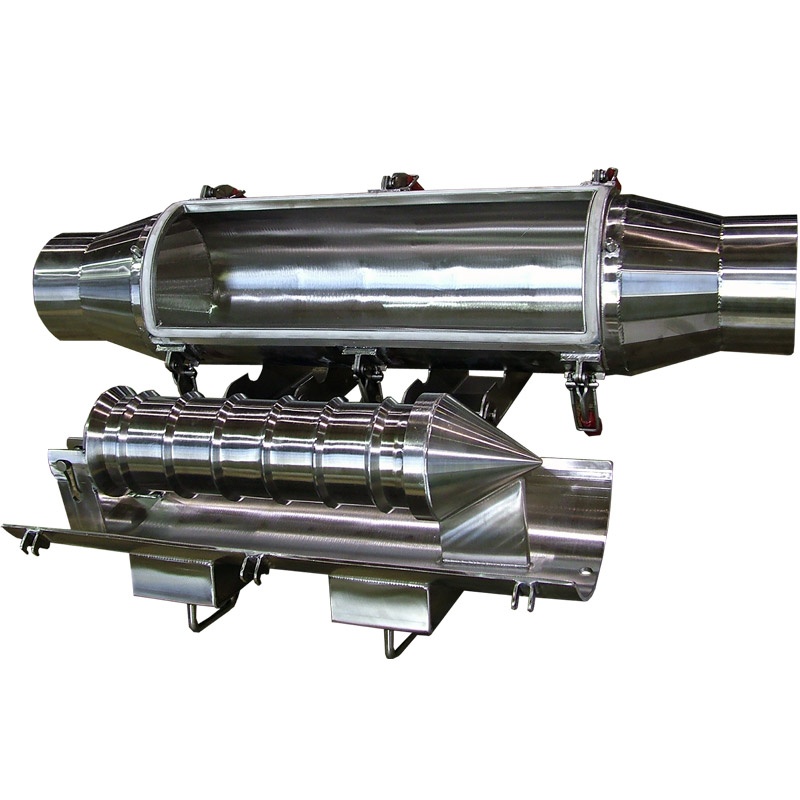

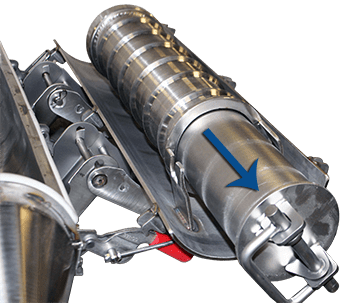

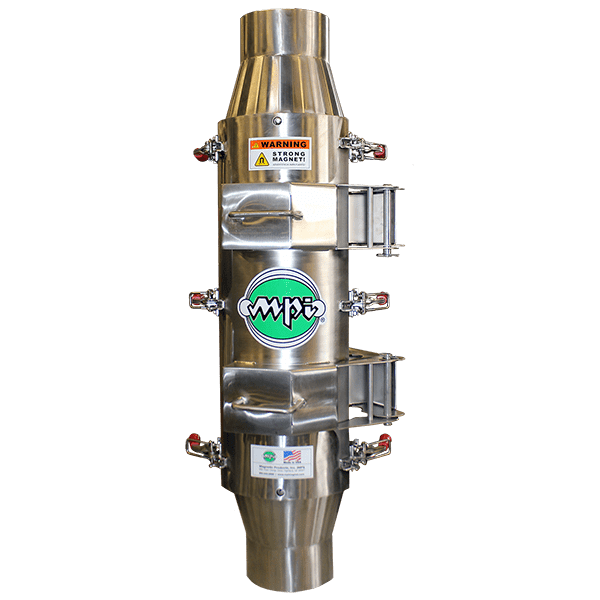

MPI Pneumatic Line Magnets are easy to install in vertical or horizontal piping. A quick-clean removable magnet element allows for rapid and easy removal of tramp metal. Its raised pole design prevents metal “wash-off” contrary to other smooth surface models. Typical applications include powder or granular food products, pharmaceuticals, plastics and chemicals conveyed at high speeds in low density, high-air systems.

Pneumatic Line Magnet Options:

- Pipe Size: Available in diameters from 2” to 10” in any increment.

- Cleaning Method:

- Manual clean

- Manual quick-clean with removable magnetic core (standard)

- Magnet Element:

- 7 raised poles (standard on sizes up to 6”)

- 5 raised poles (standard on sizes 7” and larger)

- Material Construction:

- 304 Stainless steel with 430 stainless steel raised poles (standard)

- 316 Stainless steel, including raised poles (reduces pull value on contact compared to 430 stainless poles)

- Magnet Material & Temperature:

- 400°F (204°C) @ 3.5 MGO (ceramic)

- 176°F (80°C) @ 52+ MGOe (rare earth) (standard)

- 248°F (120°C) @ 48 MGO (rare earth)

- 356°F (180°C) @ 38 MGO (rare earth)

- 662°F (350°C) @ 30 MGO (rare earth)

- Gasket Material:

- White silicon, FDA approved (standard)

- Buna, FDA approved

- Metal detectable blue silicon, FDA approved

- Customer specified

- Inlet Flange Design:

- 3” plain end for compression coupling installation (standard)

- Cam Lock: male adapter

- Cam Lock: female adapter

- ANSI 150-pound flange

- Customer specified

- Outlet Flange Design:

- 3” plain end for compression coupling installation (standard)

- Cam Lock: male adapter

- Cam Lock: female adapter

- ANSI 150-pound flange

- Customer specified

- Position Switch: For unit closed confirmation or safety interlock

- Not included (standard)

- Proximity switch for unit closed confirmation (MPI Standard model and mount)

- Mechanical safety switch for unit closed confirmation and safety (MPI Standard model and mount)

- Switch mounting bracket only (customer supplied switch)

- Customer specified model

- Cart: MPI can provide a cart for the separator so it can be transported easily, commonly used for bulk unloading and/or loading areas.

- Not included (standard)

- Included