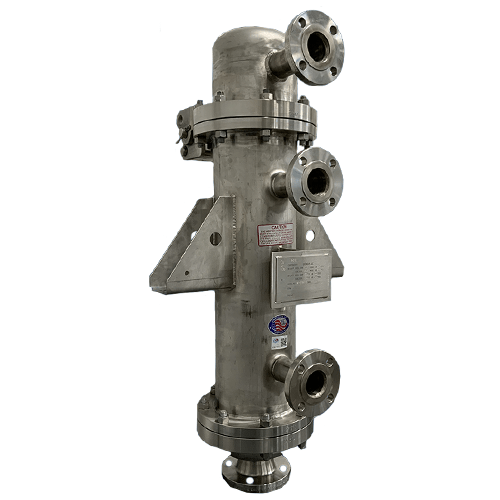

Pharmaceutical Heat Exchangers

Standard Pharmaceutical Design Features

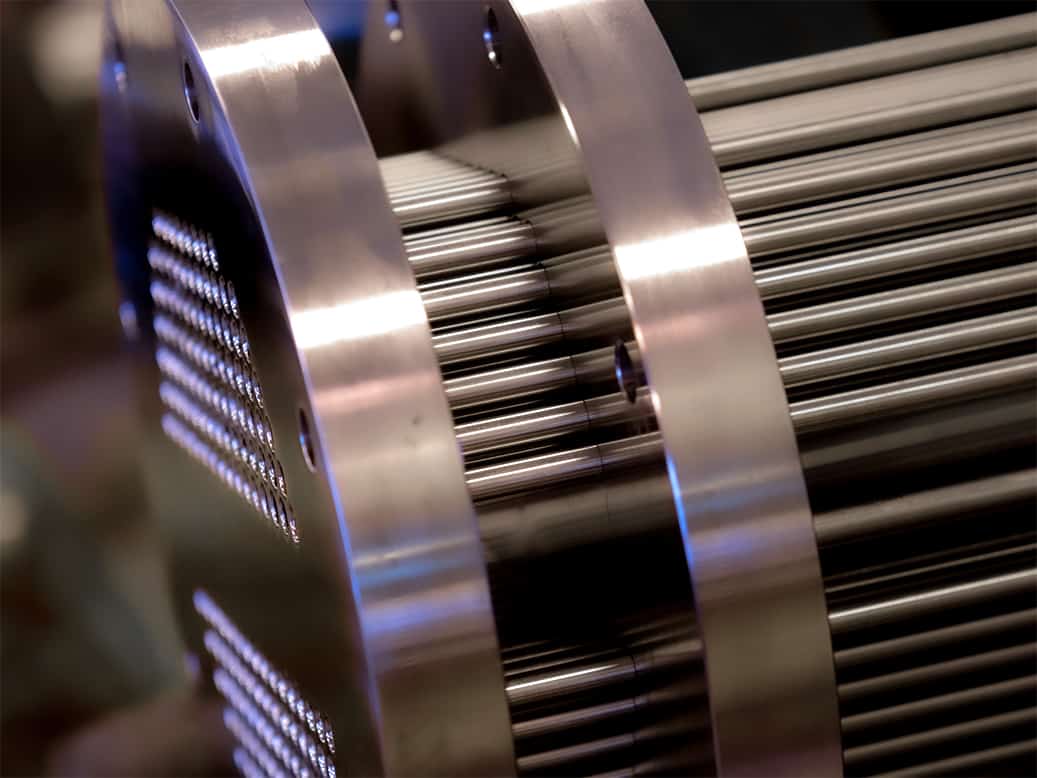

Roller Expanded, Seamless Tubes – Enerquip’s pharmaceutical exchangers will have 316L seamless tubes, polished to 25Ra or better. During fabrication, we roller expand the tubes into double-grooved tube sheets and seal weld the tubes in place which enhances stability and contamination prevention.

Surface Finish – As a standard, Enerquip polishes the exterior of our exchangers and insulation jackets to 40Ra, giving your equipment a sanitary look and feel while also enhancing its cleanability. Our in-house electropolishing capabilities ensure your equipment gets the best surface finish available, while allowing us to control cost, quality, and lead-time.

Pitched for Cleanability – Enerquip’s pharmaceutical exchangers are pitched to encourage gravity draining of both sides of the unit. The weep slots incorporated into the pass partitions help to facilitate draining of fluids. Our return pockets and weep slots are also fully radiused and polished to enhance cleanability and draining. Due to surface tension in highly polished tubes, air or heat may be required to fully drain exchangers.

Downloads: