Description

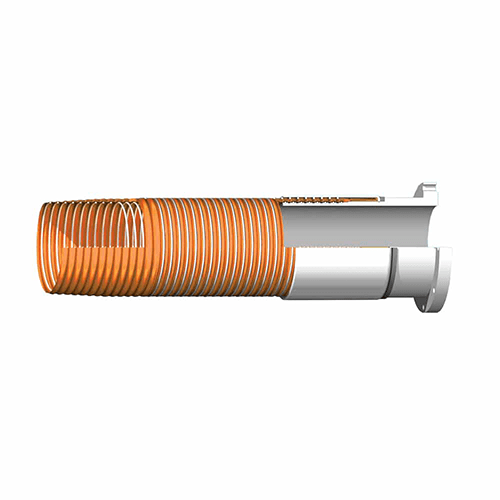

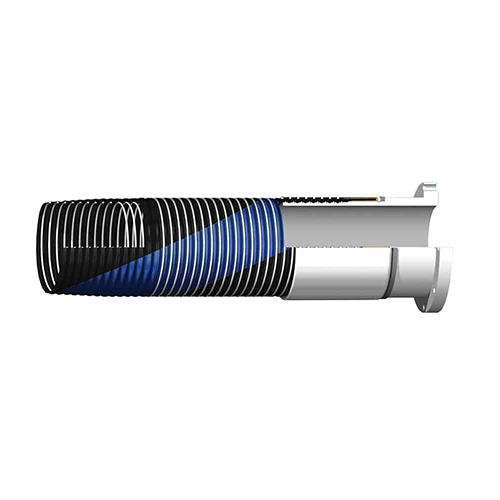

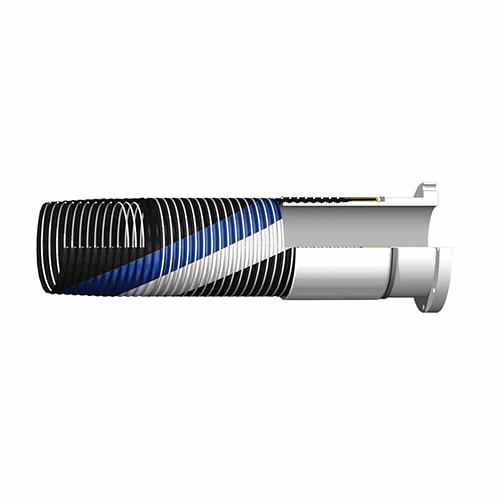

Construction

- Color/Cover: Orange/PVC Coated Nylon, Abrasion, UV and Ozone Resistant

- Inner Wire: Aluminum #5052

- Inner Lining: High Density Polypropylene

- Carcass: Polypropylene Fabrics and Nylon Films

- Outer Wire: AAD Aluminum #5052; AGO Galvanized Steel

Physical Properties

- Temperature Range: -22°F to +212°F (-30°C to +100°C)

- Maximum Elongation: ≤10% on test pressure

- Vacuum Range: 26 inHg (660 mmHg), 0.9 bar

- Electrical Properties: Electrically Conductive; ≤2.5 ohm/m for sizes less than 2″; ≤1.0 ohm/m for size 2″ and above

End Fittings

Fittings are designed with a specially machined helical shank which enables it to be screwed into the matching internal helix wire. The external ferrule can be either crimped or swaged.