Description

Technical specifications

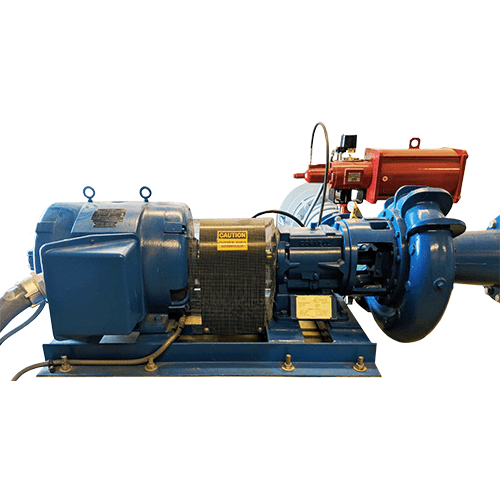

High Efficiency Components

- Radial Flow Outflow Turbine: 80% max*

- Epicyclic gear box @ 300 kW rated

- Induction Generator: 96% at 275 kWe

Full Load Operation

- Power Output: 275 kWe (@ 480 V, 60 Hz, 3 Phase)

- 2,400 MWh annual generation (@ full capacity)

- Steam heat rate: 3,690 Btu/kWh

Operating Parameters

- Maximum inlet pressure: 350 psig

- Minimum discharge pressure: 1 psig

- Typical letdown duty (inlet/outlet, psig): 350/100, 150/30, 125/15

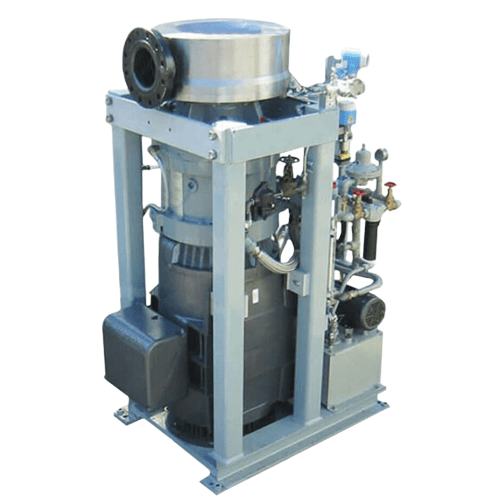

Compact Design

- Installs through standard door

- Minimally invasive to existing steam system

- 34″ x 42″ x 78″ vertical configuration

Robust construction

- 20+ year lifetime

- Minimal maintenance

- Tolerant of poor-quality steam

- Stainless steel nozzle

Control system

- PLC with color display

- Pre-wired, factory-tested

- Single-button startup

- Automatic synchronization

- Unattended operation

- Hardwired safety trips

Electrical considerations

- Pre-wired, factory-tested instrumentation

- Quick connect cables

- Plug-and-play

- Minimum installation costs

Quiet operation

- 85 dBA untreated acoustically

*Turbine efficiency is dependent upon pressure ratio. Third party study verifies maximum efficiency.

**Flow conditions outside of this flow range may be acceptable.