Description

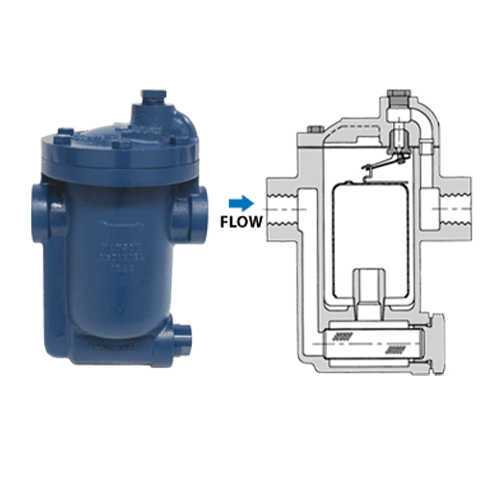

Inverted Bucket Series Steam Traps with Strainers are used in drip applications to remove condensate from steam mains and steam supply lines.

The smaller sized units have an adequate capacity for drip applications.

The discharge orifice of the inverted bucket trap is mounted at the top of the trap body. This makes them less susceptible to clogging from dirt and debris.

IB traps have poor air-handling capacity. They are only recommended for process applications where discharging air during system start-up is not a critical factor.

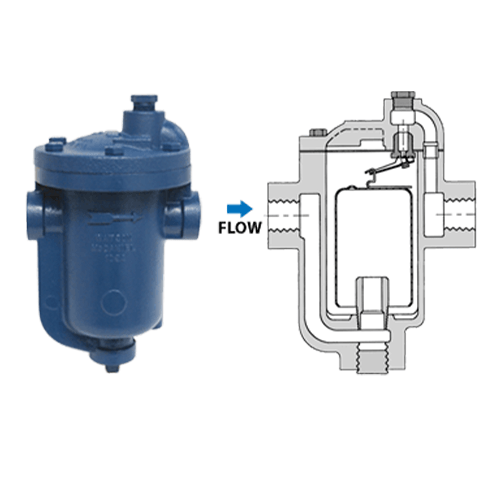

Ideal for applications such as united heaters and laundry equipment.

F&T traps are the preferred choice for systems where air MUST be quickly discharged.

Application Data Sheet – Fill Out and Return for Accurate Quote