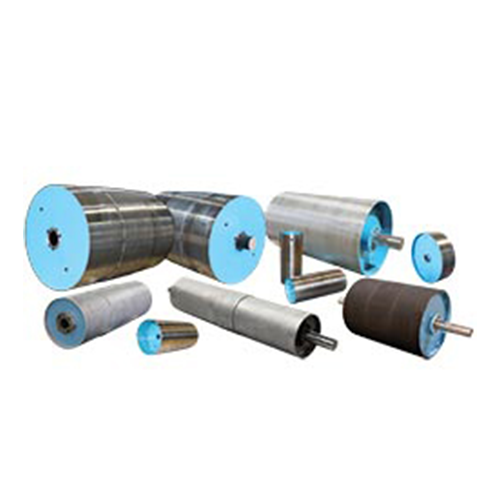

Description

Magnetics Separation Pulleys offer superior removal of ferrous steels from ASR and ICW applications. Typically used with either Deep Reach Ceramic or Deep Reach Neo Rare Earth Pulleys. Magnetic Separation Head Pulleys are extremely popular to continuously remove, recover, and discharge ferrous metals. They are used with Shredded ASR streams before Eddy Currents or in ICW streams before Wire Choppers. They can also be used for continual separation of ferrous from non-ferrous steels in your scrap metal recovery separation