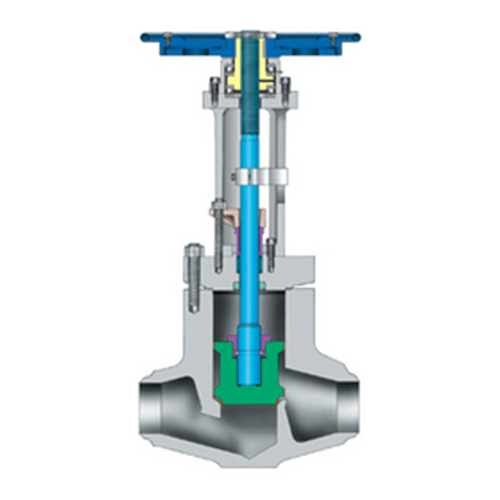

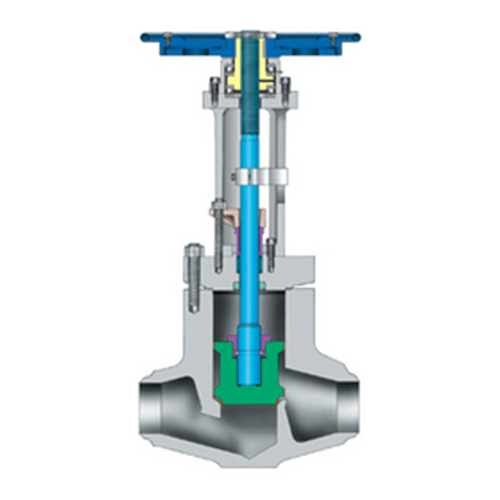

Description

Size Range(s)

- NPS 2-1/2 – 24

- (DN 65 – 600)

Pressure Rating

- ASME Classes 150 – 1500

Standard Connections

- Butt Weld, Flanged

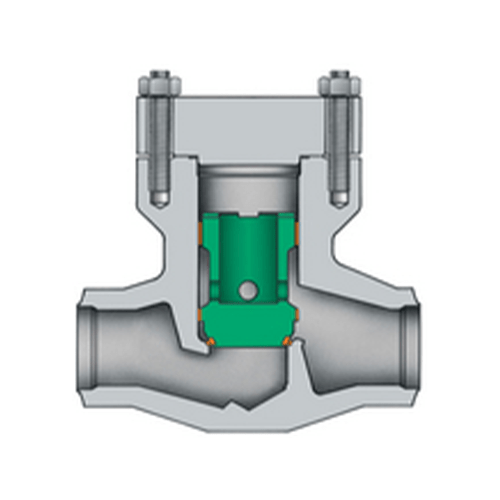

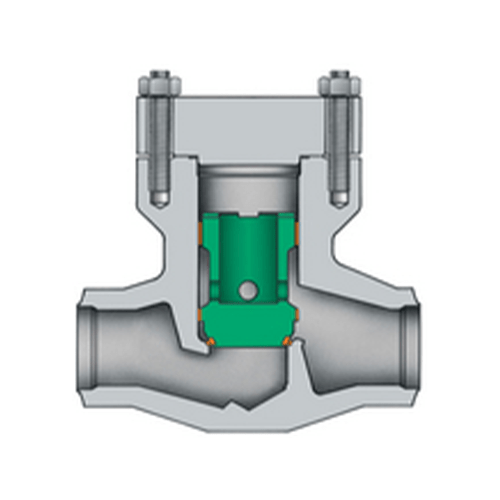

Check valves are installed to allow flow in one direction only and they protect systems that can be affected by reverse flow, such as a system shutdown. They are operated entirely by reaction to the flow and therefore do not require external actuation. Care and attention should be paid to check valve installation orientation. For information please consult the appropriate Installation Operation manual (IOM).

Size Range(s)

Pressure Rating

Standard Connections