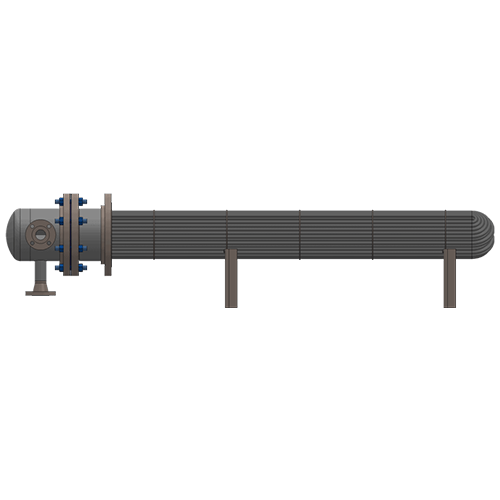

Description

Applications

Enerquip’s bayonet heaters are versatile and can be used in a wide range of applications that require efficient heating of tanks or vessels. Here are some examples of industries and processes where these heaters are commonly used:

- Chemical Processing: Heat liquids such as acids, solvents, and other corrosive materials.

- Oil & Gas: Used to heat storage tanks, pipeline transfer stations, and refineries.

- Asphalt: For the heating of bitumen, which is a highly viscous, semi-solid form of petroleum.

- Food & Beverage: To heat liquid products, such as dairy products, sauces, and beverages.

- Pharmaceutical: Used to heat tanks containing various chemicals, including active ingredients, solvents, and other raw materials.

- Water Treatment: To heat water or chemicals used in the treatment process.

- Power Generation: Used in power generation applications to heat water or steam used in power plants.

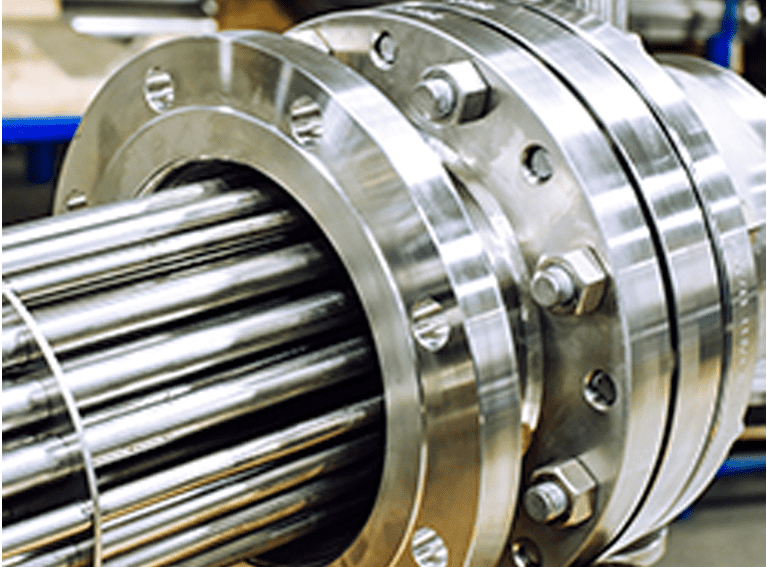

These heaters can be customized with carbon steel or 316L stainless steel materials.