Air-Cooled ElectroMax Suspension Magnets

Bunting supplies various types of plate-based magnetic separators that can be implemented into a broad range of applications and can be used with an equally wide range of materials. All plate magnets are designed for the capture of tramp metal in gravity free-fall applications. Metal-detectable gaskets and grommets are standard features in housing of plate magnets.

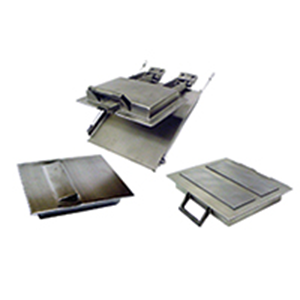

Standard Plate Magnets are available with permanent ceramic magnets or with high-intensity permanent rare earth magnets. Both types of magnets work efficiently to capture fine metal particles and slightly magnetic debris from powdery, moist, clumpy, or abrasive materials that might choke or wear cartridge-based separators. Plate magnets install easily in chutes to remove ferrous fine particles and larger pieces of tramp iron from many types of free-flowing and pneumatically conveyed material. They can also be installed above conveyors or below conveyor drive pulleys to capture contaminants as material drops from open belts. Standard installation kits include a pre-drilled hinge, latch, and other hardware to ensure easy mounting. The tapered magnetic face is designed to prevent contaminant wipe-off in rapid product flow. Standard plate magnets are available in widths from 4″ to 60″.