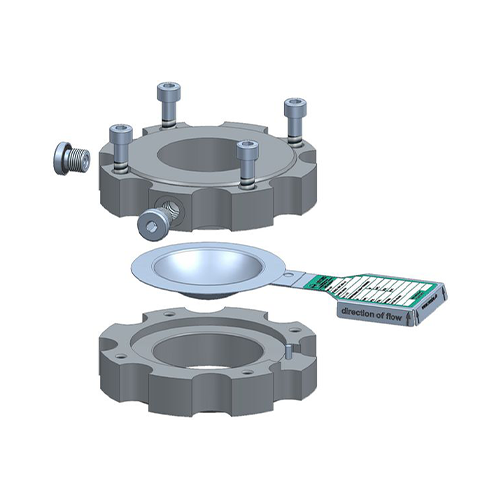

Rupture Disc Holder

The holder’s unique design guarantees that the rupture disc is always inserted correctly. A full metal clamp ensures the seal is tight. This prevents the rupture disc from being damaged and allows it to be re-used after having been removed, e.g. during an inspection. The IG rupture disc holder features an inclined seat and is designed for forward acting rupture discs. The 30° oblique seating arrangement creates the optimum seal for the rupture disc ensuring leak tight integrity. The holder outlet has a slight radius to which the rupture disc is adapted. This guarantees the perfect fit of the rupture disc and maintains its optimal opening.

Applications

- Separators, autoclaves, chemical reactors, distillation towers, desalination plants, flare stacks, FPSOs, gas-tight pressure vessels, gas compressor modules, gas turbines for power generation

- Hazardous goods containers, geothermal energy, intermodal containers for corrosive/ aggressive media, isolation of safety valves, condensers, power plants, cryogenic applications, cryostats + transport containers, LDPE (thermoplastic)

- Food production, mixers, oil and gas separation and treatment, petrochemical plants, process vessels, refineries, reactors, spray dryers, sterile tanks, aseptic tanks, reverse osmosis systems, heat exchangers