Description

Application

The Q-Ball® E is suitable for low-strength plant components as well as plants at risk of dust explosions such as elevators with KSt values ≤ 200 bar × m/s.

Applications & Industries

- Aspiration plants

- Breweries

- Elevators

- Filters

- Conveyors

- Wood processing

- Food production

- Mixers

- Mills and grinding plants

- Recycling

- Screens

- Silos

- Destoners

- Spray dryers

- Animal feed production

Mechanism

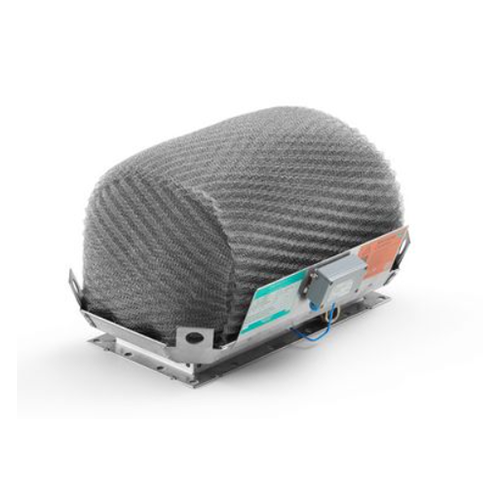

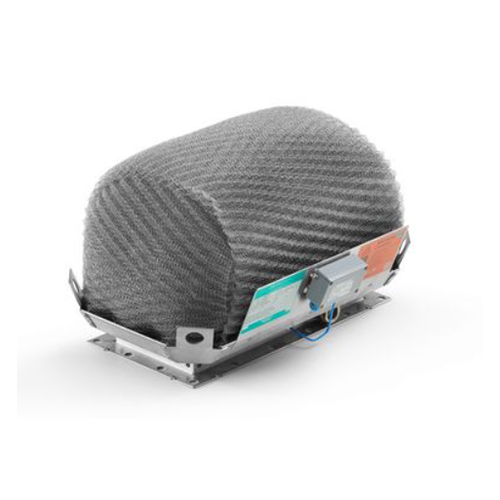

The flame gases, which can reach temperatures of up to 1,500°C, are cooled extremely efficiently in the special stainless-steel mesh filter inlet developed by REMBE®. This reduces the volume of escaping gas and thus extinguishes the explosion.

Advantages

- Maximum venting efficiency through a full body flameless venting

- Easy maintenance through an integrated inspection opening

- Integrated signaling for a reliable monitoring

- Can be utilized flexibly indoors and outdoors

- Easy retrofitting of existing vent panel installations possible