Description

How Does the Intell-I-Mag® Controller Work?

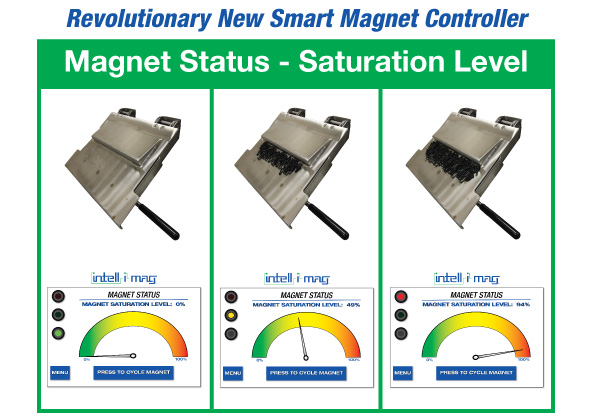

The Intell-I-Mag Controller monitors tramp metal saturation levels on the working surface of the magnetic separator in real time. The magnetic separator has sensor imbedded into the separator that measure the strength of the magnetic field. These sensors report the data collected in real time to the Intell-I-Mag Controller. The controller can then be programmed to clean the separator automatically when it reaches the user designated saturation levels.

Example 1 Finishing Magnet:

The user wants to ensure final product quality. Assuming a good upstream metal control program is in place, the largest threat to final product quality can be weakly magnetic work hardened stainless steel. If the user wanted to quickly remove lightly magnetic work hardened stainless steel immediately upon capture, it could be set the Intell-I-Mag Controller to cycle at a low % of saturation, say 5%. This configuration may be ideal for a finishing magnet to remove small and weakly magnetic tramp iron that often times cannot be identified by a metal detector or X-Ray machine. Cycling the magnet quickly after capturing ensures the captured metal cannot be washed off into the product flow and end up in the final product.

Example 2 Secondary Magnet:

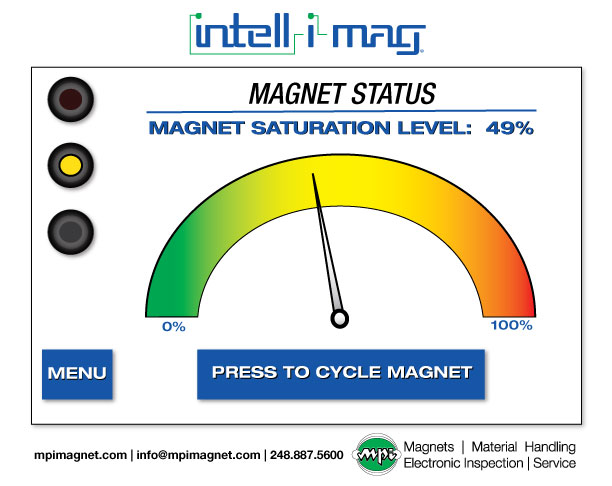

The user wants to protect downstream processing equipment, such as a hammer mill, airlock or mixer. To ensure proper protection of this equipment, the magnet cannot become overly saturated to the point that it cannot capture more metal. Intell-I-Mag could be set to notify the user when the magnet is saturated 50%, giving them time to shut down the process immediately or schedule an upcoming shutdown to clean the magnet. Preventing this metal event would save the user from unplanned maintenance, repair costs and further downstream damage, including loss of product integrity. Conversely, if the magnet never reaches the targeted saturation level, the user may not need to shut down the system to clean the magnet. This would result increase uptime of the processing system.

Example 3 Primary Magnet:

The user wants to monitor vendor unloading into their facility for the presence of ferrous metal. The best way to keep metal out of the final product is to keep it from coming into the plant in the first place. The Intell-I-Mag can be set to the user’s requirements. A strict scenario might be to stop the unloading process as soon as the presence of metal is detected or a specified threshold of magnet capacity. Alternatively, metal may be known or acceptable but the user wants to ensure the metal is removed prior to entering the facility. In this scenario, the Intell-I-Mag can alert the user to stop the unloading process and clean the magnet prior to the separator reaching full metal saturation. In either scenario, the user can be confident that tramp metal has not entered the facility from a vendor.

Learn more about magnetic applications and where magnetic separators should be placed to control metal and achieve success for removing tramp metal from your product flow.

How to Use Intell-I-Mag Data?

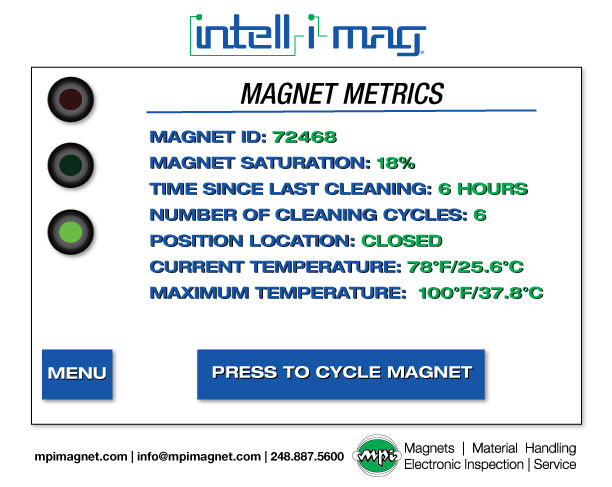

The controller provides other reporting metrics beyond magnet saturation helpful for quality compliance initiatives. The Intell-I-Mag Controller data collection improves analysis of magnetic separator performance, including magnet saturation, cleaning alerts, temperature monitoring, cleaning cycles and position location. Operators can establish a higher level of metal control and create a stronger quality management plan for programs such as HACCP, ISO, BRC, IFS and SQF. The system can be integrated with plant control system through programmable inputs and outputs.